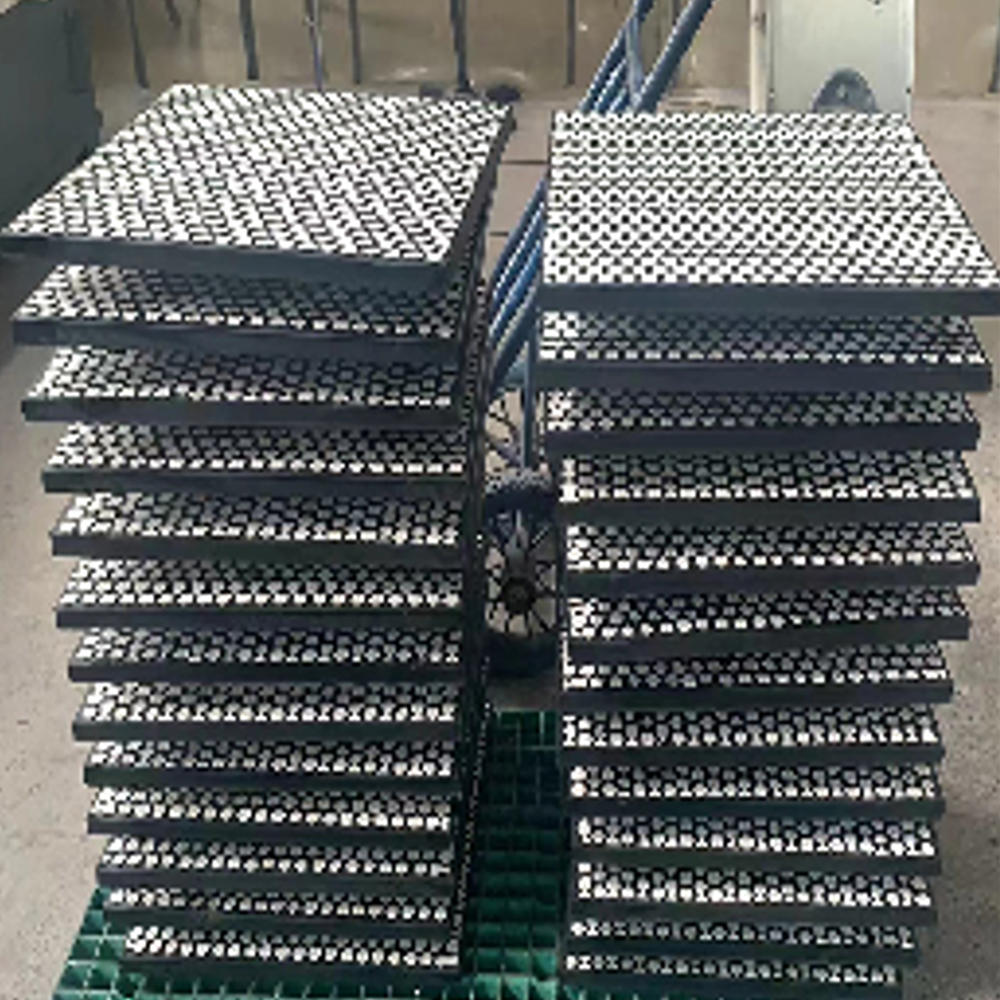

Crusher Wear Linings

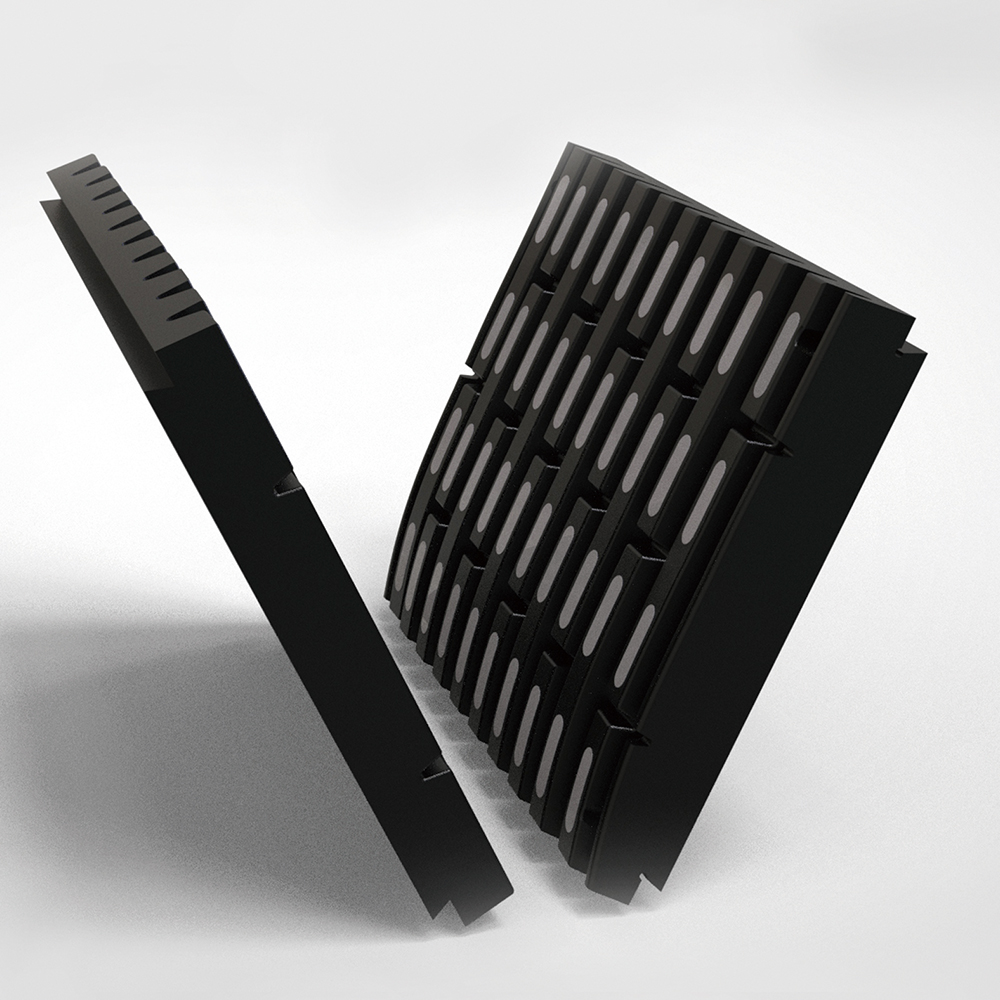

Installed in chutes, spouts, hoppers, transfer points, and other applications subjected to wear.Long-lasting and robust wear linings play a crucial role in enhancing process flow and increasing machine uptime.They also ensure safety and provide a more sustainable option.Polyethylene wear lining is manufactured from ultra-high molecular weight polyethylene (PE-UHMW) for installation in light-duty applications with clogging problems and sticky materials. The main characteristic of polyethylene is its low surface friction. They can also be manufactured using rubber and polyurethane.

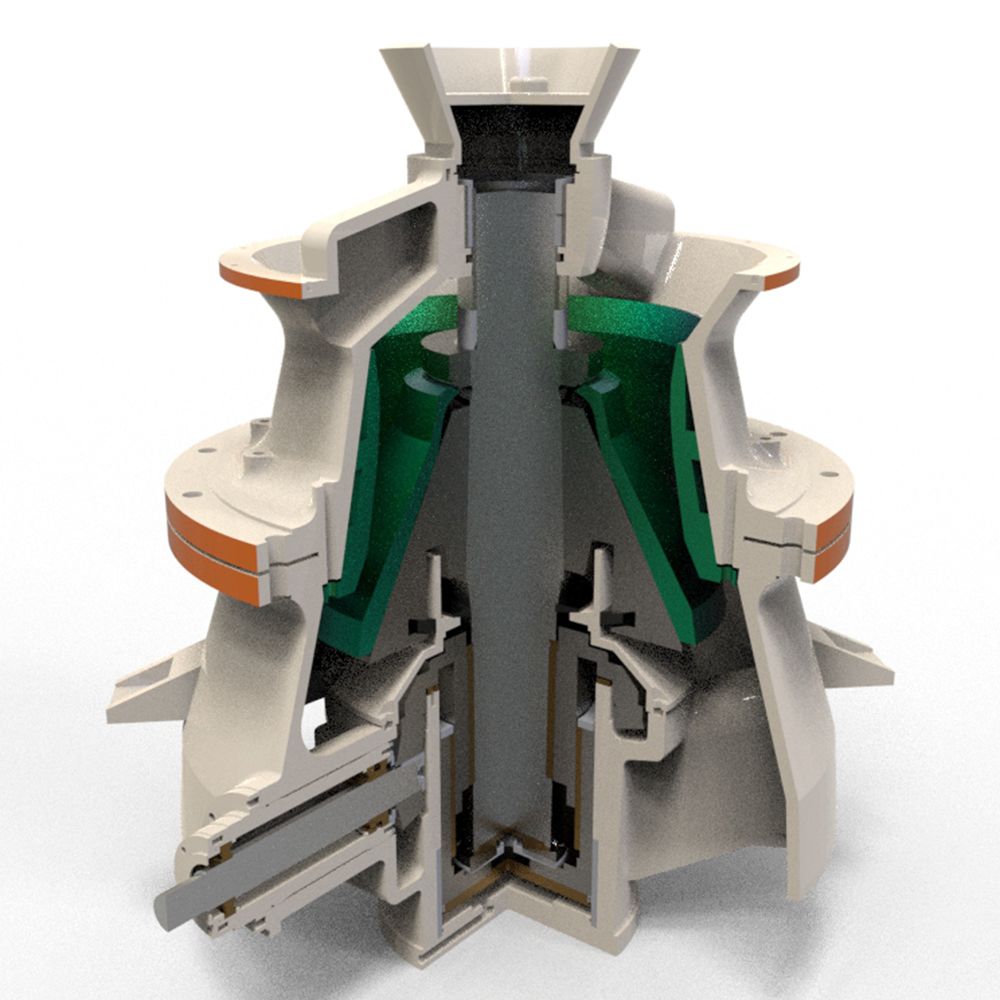

An optimal crushing process reduces the ore to a desired size more efficiently, economically and safely. The high-capacity, reliable and energy efficient crushing solutions deliver superior performance and maximized throughput also for the most demanding mining applications.

Crusher Wear Linings