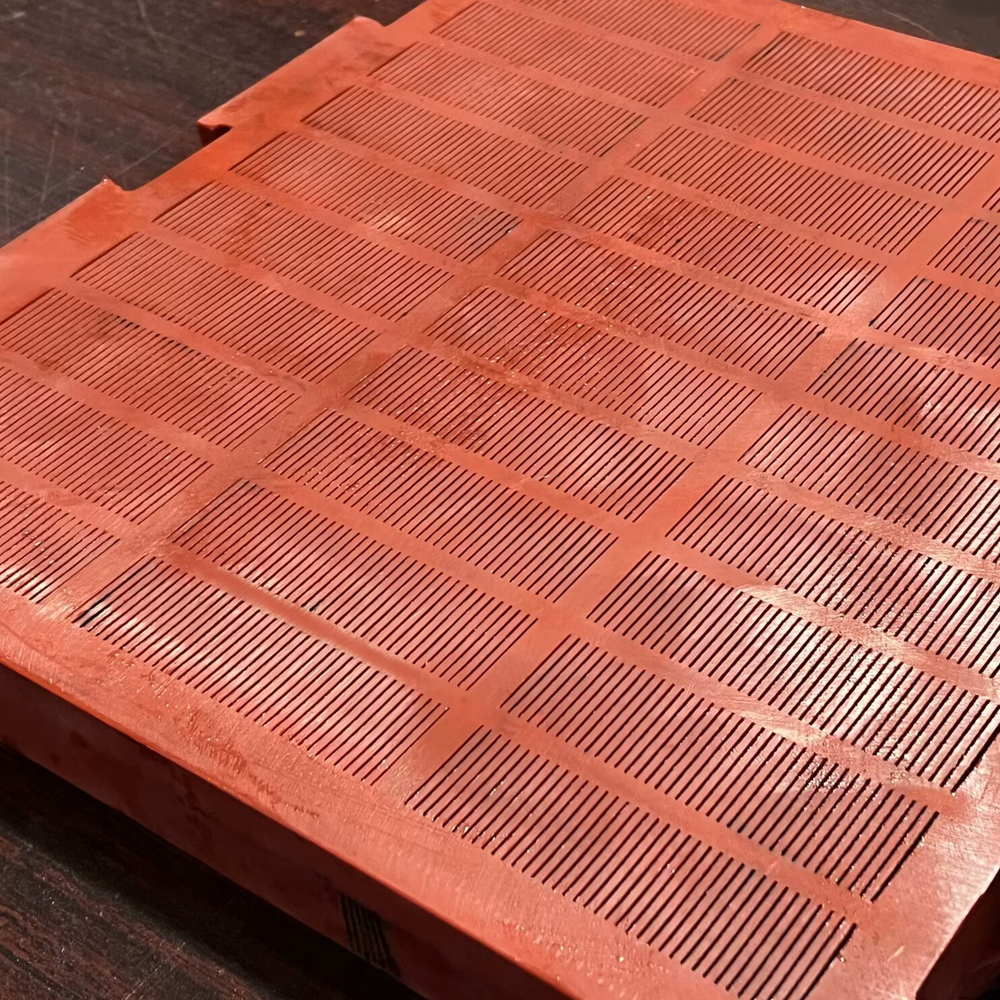

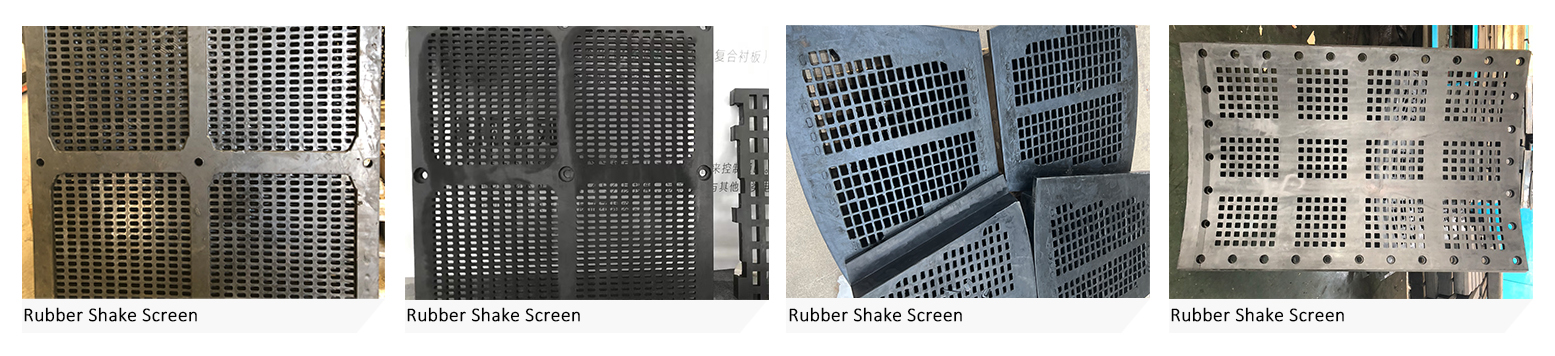

Rubber Shake Screen

Screen plate and screen are the main executive parts for separating particle size. Due to the impact and friction of the screened material on the screen, the screen is worn very quickly. generally speaking φ 10. The steel screen woven with round steel will screen iron ore (after fine crushing), and its service life will not exceed 15 days; Moreover, serious hole plugging will occur during operation, which will exceed more than 50%.

Using imported natural rubber materials with high resilience to make the screen mesh and screen plate fundamentally solves the above problems. It has the following characteristics:

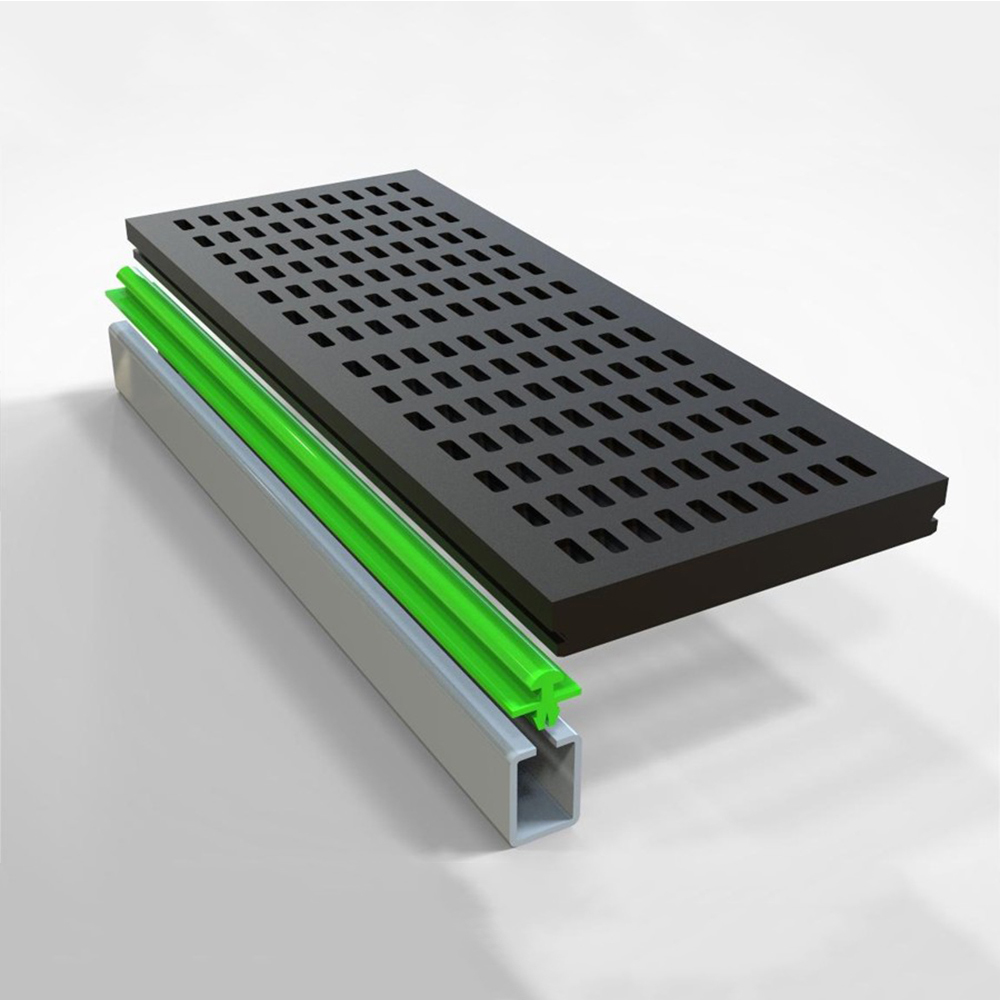

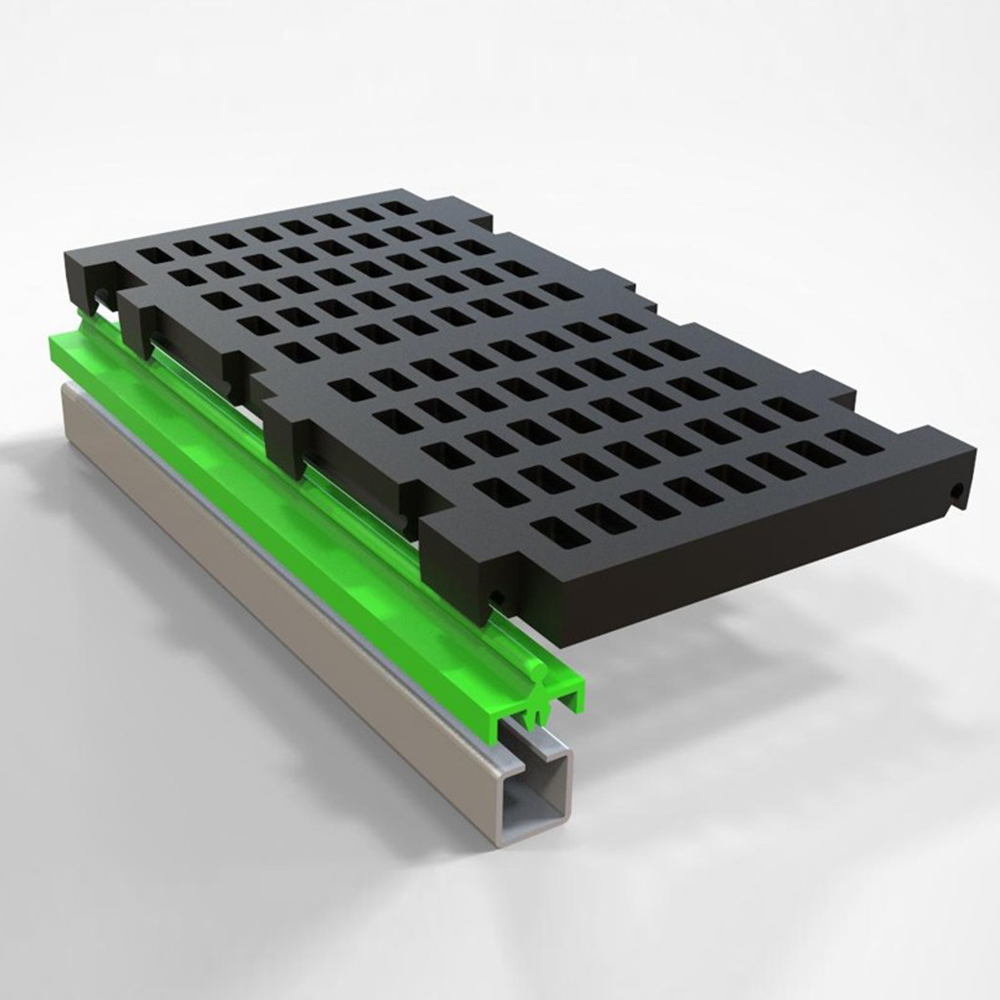

1、Light weight, reduce energy consumption;

2、Damping effect, reducing noise by 15dB;

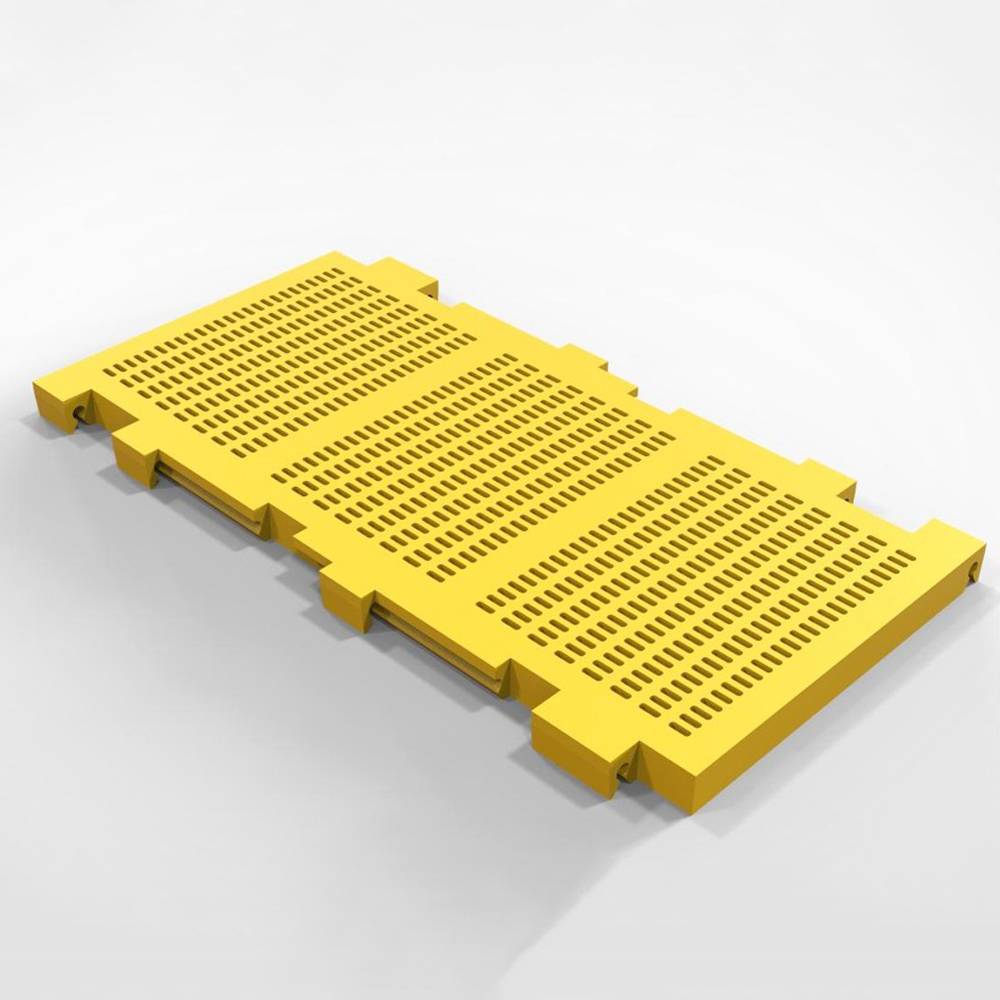

3、 Reasonable structure and convenient disassembly;

4、Good resilience, which can increase the rebound force of materials, avoid ore scaling and improve the screening efficiency;

5、The rubber screen is flexible, and the probability of ore jam in the mesh is very small. Under the condition of the same mesh rate, the yield of the rubber screen is more than 1.3 times that of the steel mesh (omitted from the ore penetrating machine).

6、Long service life, generally 15 ~ 20 times that of ordinary steel screen.

PHOEE rubber screen classification products can be provided in two materials, rubber and polyurethane, according to the on-site requirements of customers.

1.The specifications of the sieve plate include various grooves, square holes, round holes, and special-shaped holes, etc.

2. The rubber is made of imported natural latex from Malaysia, featuring high wear resistance and high elasticity. Professional formula design is carried out for rubber screen plates, making it suitable for various impact and wear screening conditions.

3. Polyurethane is made of imported high-performance polyurethane, featuring ultra-high wear resistance and high impact resistance.

4. The design team adopted anti-fatigue designs such as finite element analysis (FEA), and through EDEM simulation analysis, designed the most reasonable and optimized sieve plate structure.

The PHOEE rubber multi-layer high-frequency vibrating screen adopts the international advanced design concept and uses a forced multi-path slurry distribution method, which reduces the slurry flow rate on the screen surface, has a long service life, a compact structure and low noise. Compared with the cyclone, the classification efficiency is as high as over 80%.

Due to the high classification efficiency and the small amount of qualified products returned, the feed of raw ore can be increased, and the processing capacity of the system can be enhanced by about 10-20%.

It can reduce the over-crushing of ores and increase the metal recovery rate by 1-3%, and for some rare metals, it can reach 10%. Due to the reduced return volume, the useless work done on the returned materials can be saved. It only needs to flow directly from the feeding end to the ore feeding end, without the need for pressurized ore supply, which is about 20% more energy-saving than the cyclone.

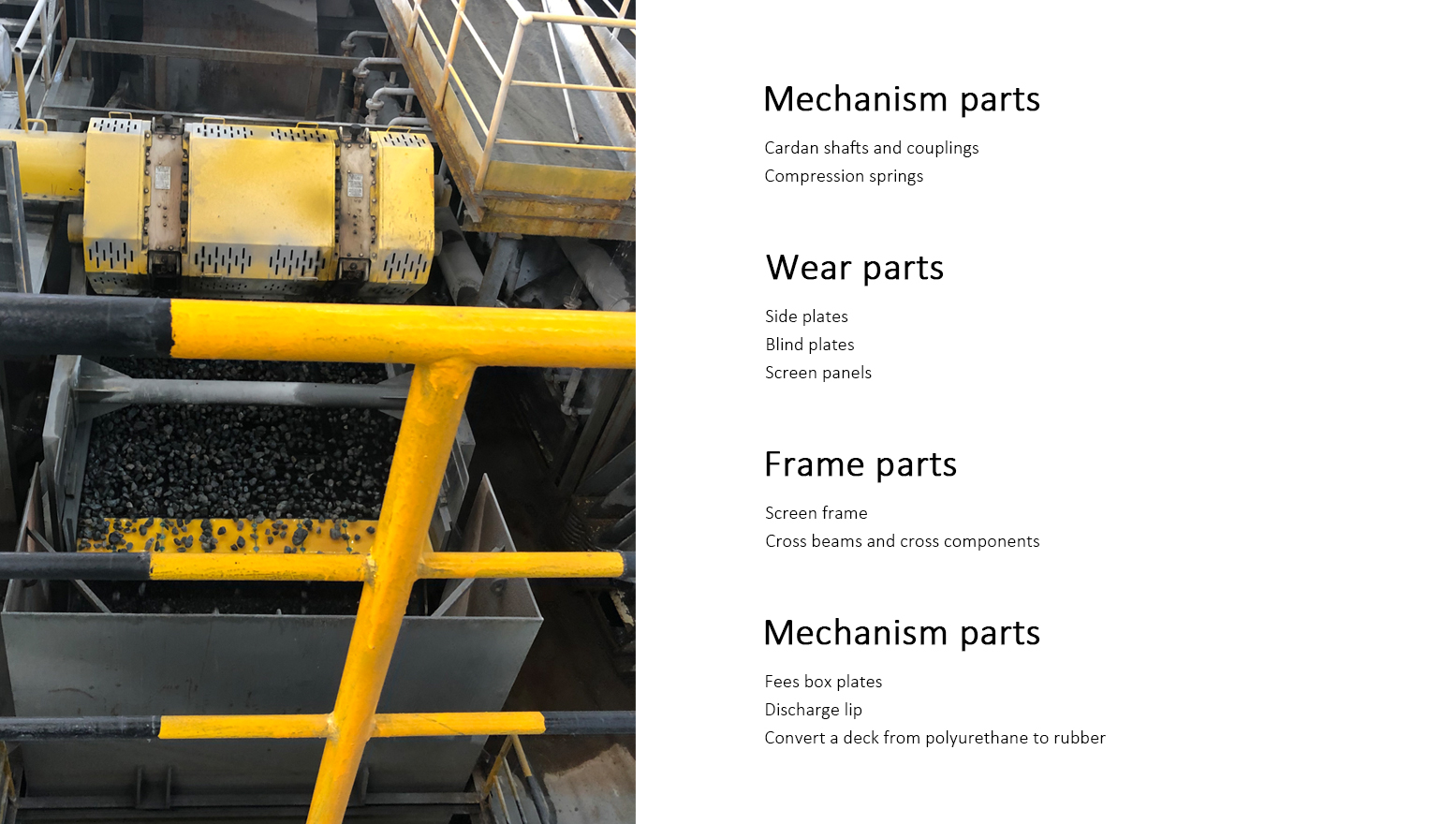

The original accessories of TIKTOP are uniquely designed with ingenuity, committed to achieving perfect fit and excellent functional performance. Each accessory has undergone meticulous research and development as well as strict testing to ensure it perfectly matches the device in various usage scenarios and performs its intended function without any deviation.

We offer assurance by selling quality parts that are long-lasting and give you peace of mind.

Whatever your process requires, TIKTOP has the screening solution to fit your needs. We offer replacement screens and all the required spare parts for your screens as well as for heritage branded screens and feeders.

Rubber Shake Screen