Vacuum Filter Belt

The vacuum belt filter belt is a key component of the vacuum belt filter. This kind of tape is usually made of high-strength, corrosion-resistant and wear-resistant materials to ensure stable performance during long-term use.

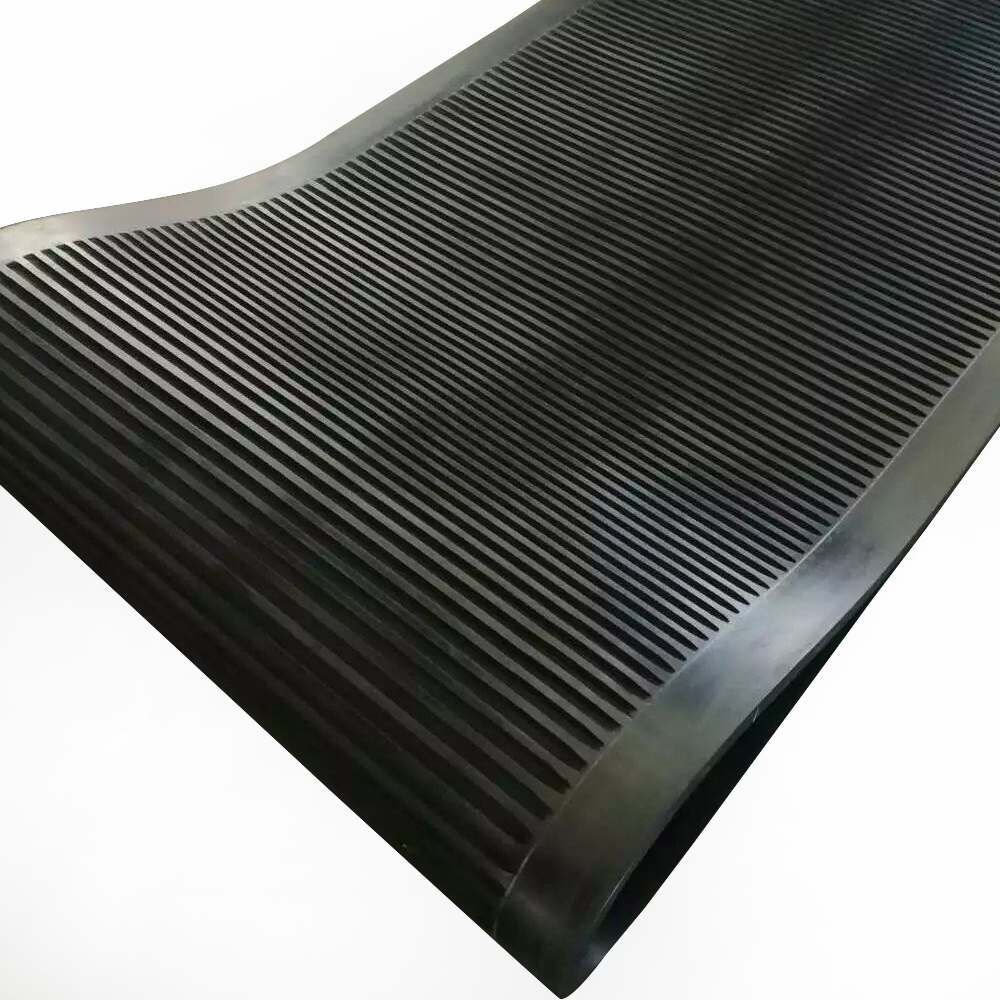

The belt of the vacuum belt filter plays a crucial role in the filtration process. It carries the materials that need to be filtered. Under the effect of vacuum, the liquid is sucked out through the pores of the belt, while the solid particles are retained on the belt, thus achieving solid-liquid separation.This kind of tape has excellent flexibility and tensile strength, can adapt to materials of different shapes and sizes, and can remain stable during operation without any shaking or deviation. Meanwhile, its surface is usually specially treated, featuring excellent wear resistance and anti-sticking properties, which can prevent materials from accumulating on the belt and ensure the stability of the filtration effect.

The frame material of the filter belt is made of polyester canvas with excellent performance, featuring high strength, acid and alkali resistance, heat resistance and oil resistance. Its notable feature is that it has a small elongation under a constant load and is not prone to deformation. The size is stable, the operation is normal after being adjusted on the machine, and it does not elongate in future production. The materials selected for the filter belt: SBR rubber is used, and polyester EP200 fiber cloth is used as the skeleton material.The rubber filter belt process: The rubber filter belt is formed and vulcanized through a one-time integral composite process to ensure the flatness of the belt body and the stability of its performance. Both ends of the vulcanized joint are reserved with raw heads and vulcanized in one piece to ensure no cracking.

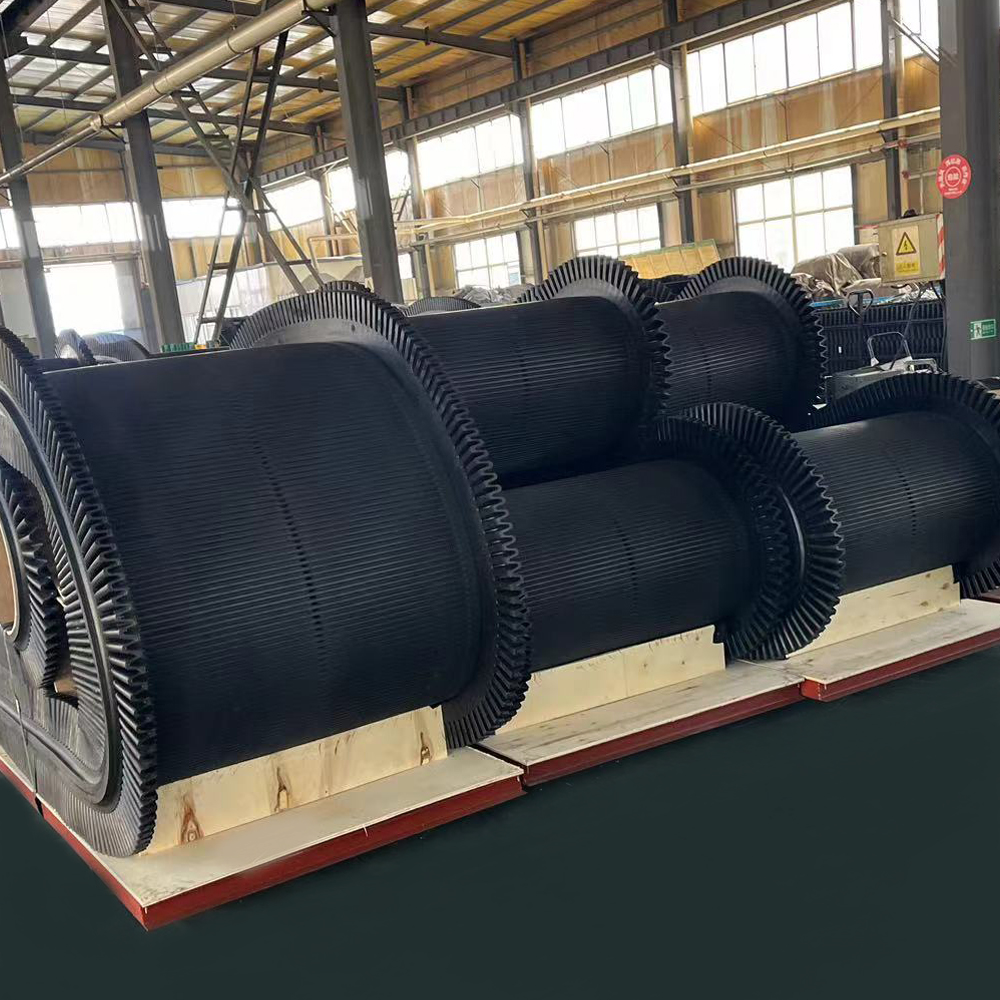

We can produce circular belts with a width range of B1000-6800mm. Our company's 6800mm ultra-wide filter belt is the first of its kind in the domestic industry. The thickness of the filter belt is 20-50mm, the thickness of the upper adhesive covering rubber is 10-30mm, and the thickness of the lower adhesive covering rubber is 5-15mm.

1. It is formed in one piece by a 5,500-ton high-pressure flat vulcanizing machine.

2. The product has high flatness, few defects and balanced internal stress.

3. Adopt fully automatic grooving process and mold pressing grooving process;

4. Customize the formula according to customer requirements, which is resistant to acid and alkali, solvents, high temperatures and crystallization.

5. Precise size control, good vacuum degree, and no leakage;

6. Long service life, generally twice that of ordinary filter belts.