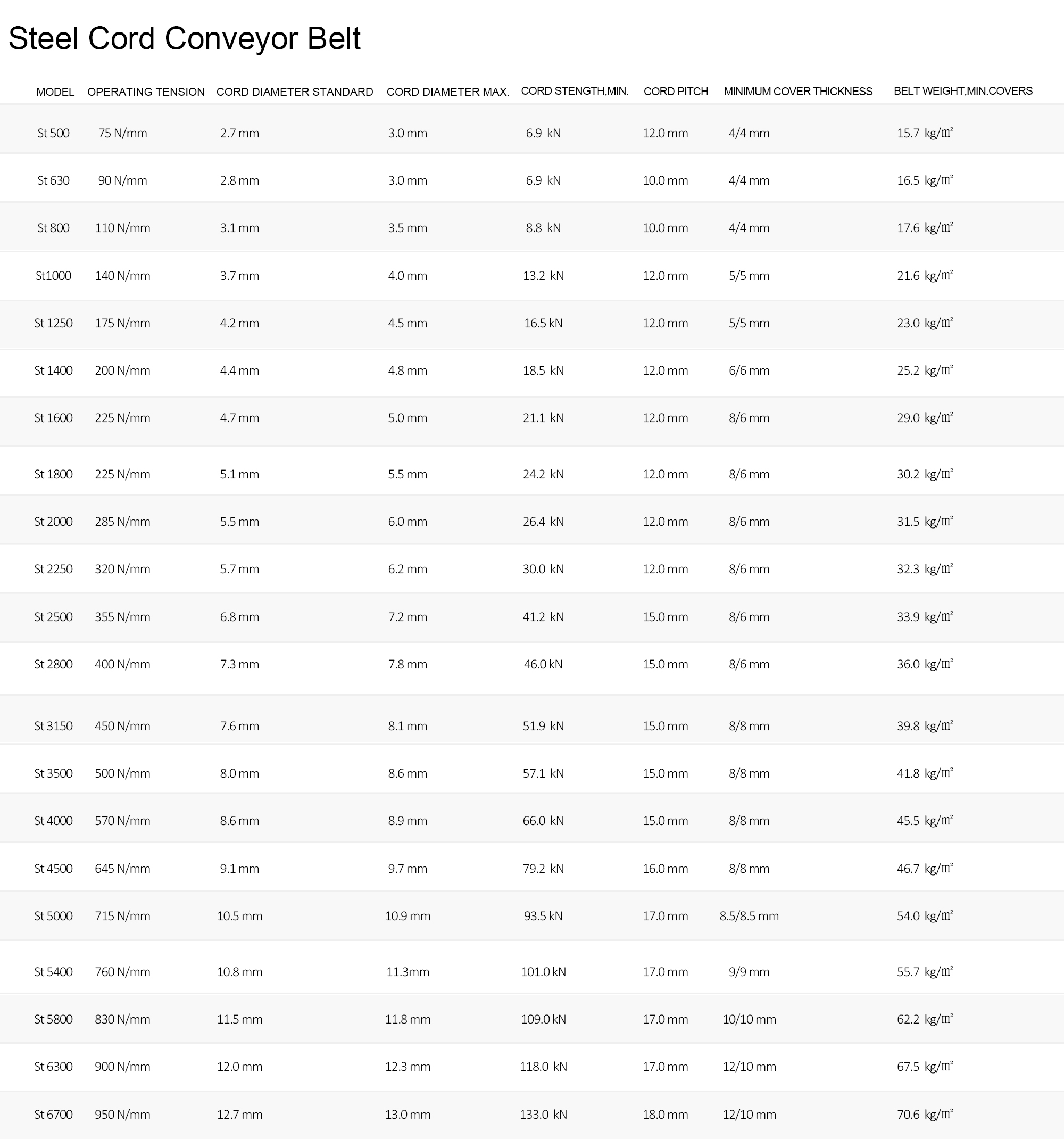

Steel Cord Conveyor Belts

Reinforcement properties

Made of high-tensile steel cords and various cover grades . A typical carcass with 7 x 7 hot-galvanized steel cords provides a tensile strength of up to 2,000 N/mm.Also available as 7 x 19 for higher tensile strength (10 000 N/mm).Standard cords have an elongation of 0.22 - 0.28%. High structural strength and pull-out strengthensure good resistance against fatigue. The open cross-lay design of the cords and the chemical adhesive system ensure that the core rubber penetrates thoroughly,bonds well and protects against corrosion for long-term integrity.

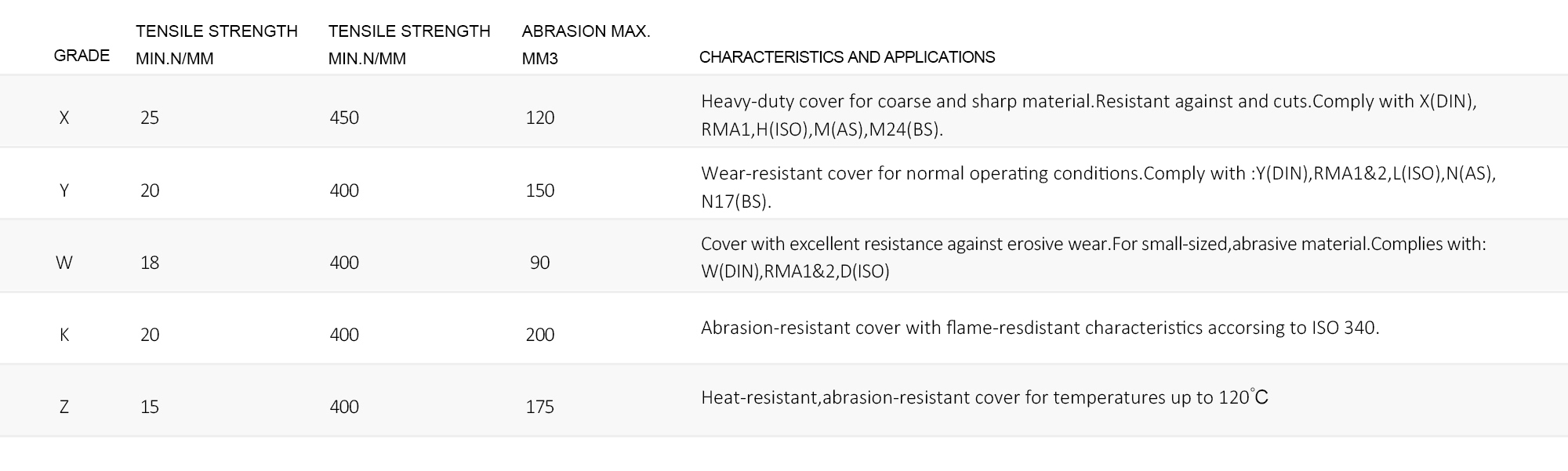

Cover grades

The belts come with various cover grades, all made of high-quality rubber with extremely high resistance to abrasion, cutting and impact and with excellent ageing properties.The choice of cover grade will depend on the application and will also determine the working life of the belt. Matching the right belt to your application means generating less waste in the long run — helping you to reach your sustainability targets.

Wear-resistant

Available in X, Y, W grades (and similar) for heavy-wear conveying applications such as bulky, sharp materials like heavy, abrasive rocks. High-quality cover grades are recommended to offer the best protection to the belt carcass.Heat-resistant Different types of grades are available for high-temperature applications (T120 and T200) such as clinker, coke, foundry sand and slag. Can be used for transporting material at continuous temperatures of up to 190 °C, with peaks of up to 200 °C.

Flame-resistant

Available in flame-resistant grade K to comply with ISO 340. Can be used in tunnel projects but not underground applications.Contact your Phoee expert for more information and advice regarding the best choice of belt and cover grade for your operation.

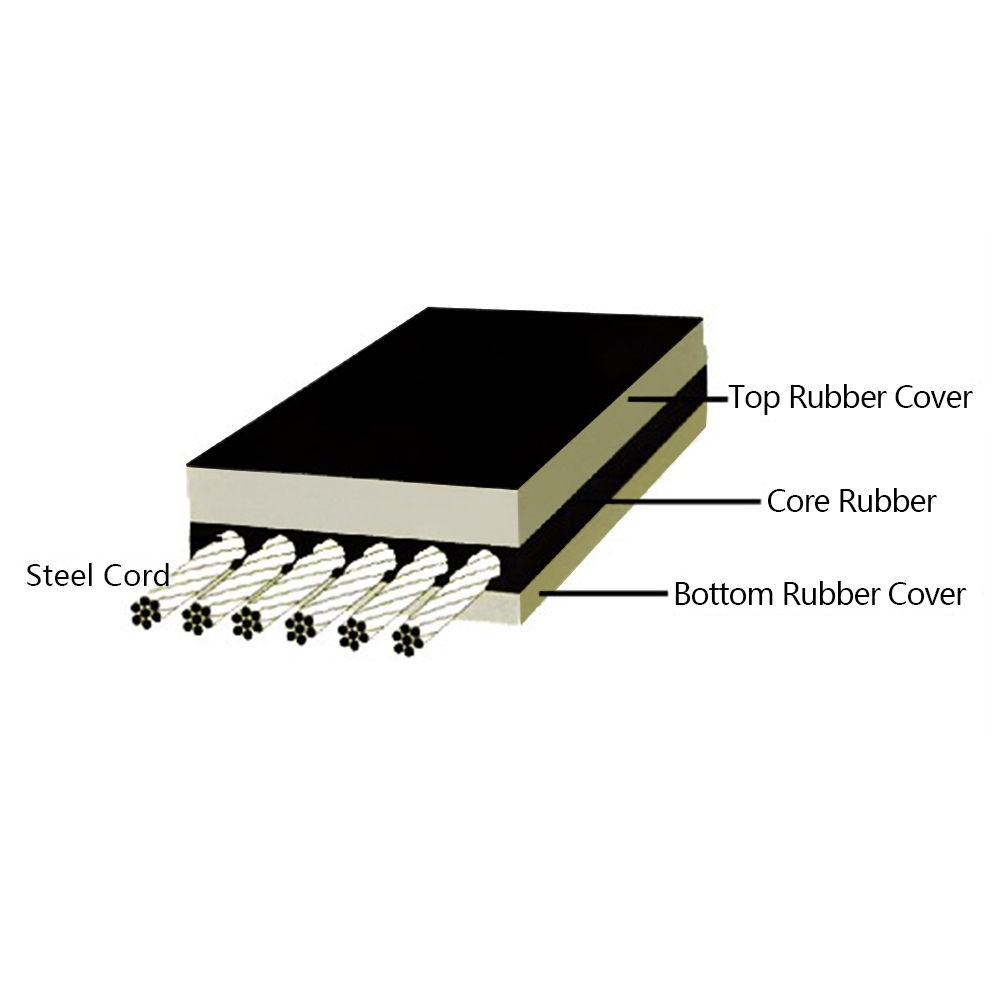

Steel cord

In the manufacturing of conveyor belts, steel ropes often play a crucial role. Among them, steel ropes are widely used to achieve high-strength performance. This high

strength enables the conveyor belt to carry heavier materials and adapt to various heavy conveying tasks. Meanwhile, the use of steel ropes can also bring excellent length stability.

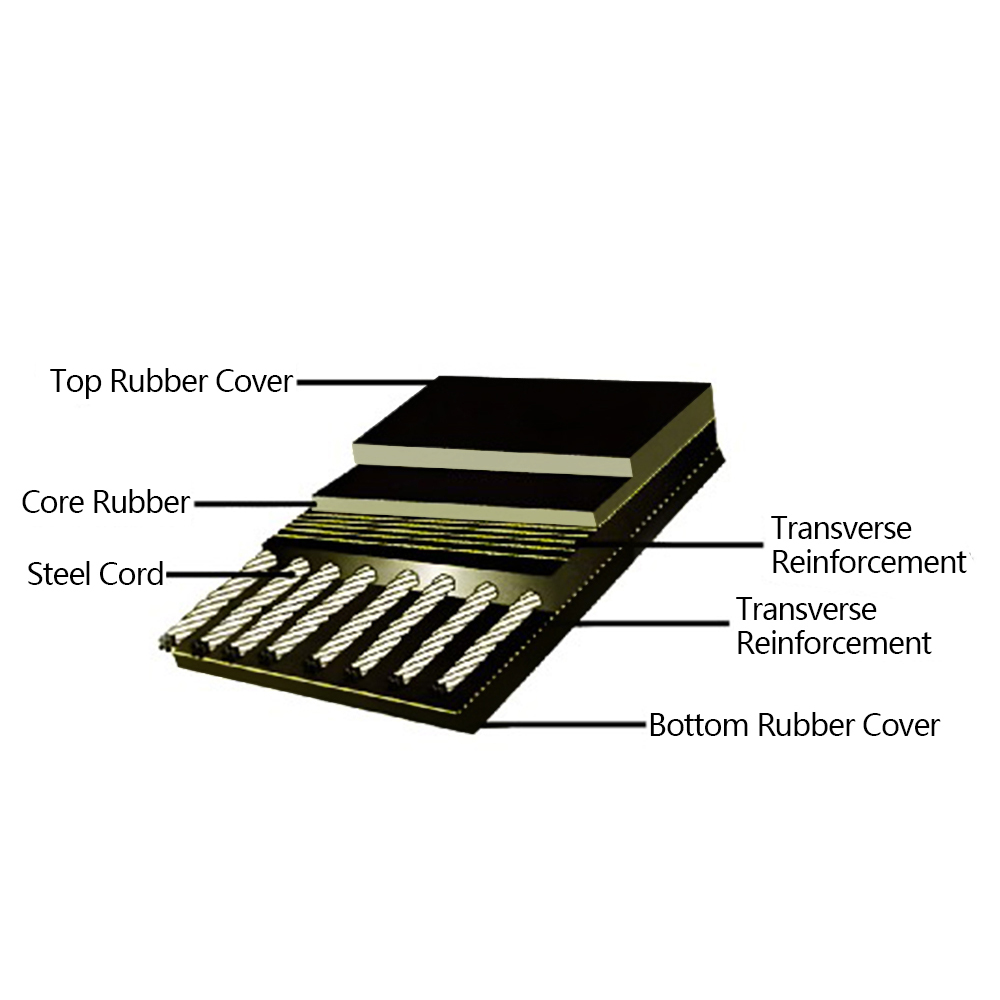

Leno Weave

It adopts a unique transverse steel mesh structure, which can prevent long-distance tearing when the steel wire rope conveyor belt is longitudinally damaged and provide

more tear resistance.

Steel Cord Conveyor Belts