Sidewall conveyor belts

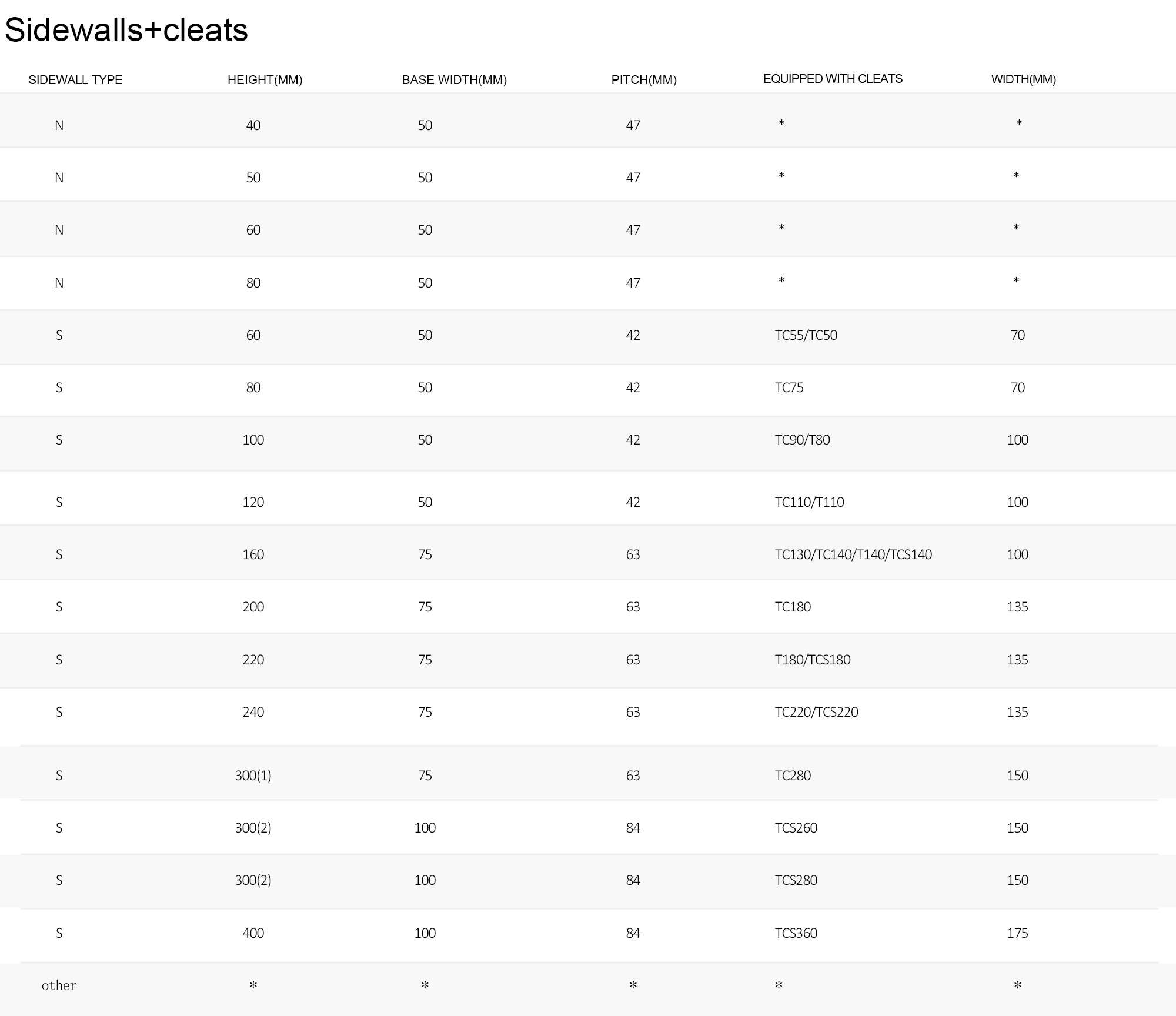

When you need to transport material at steeper angles than is possible with conventional conveyor belts, sidewall belts are the way to go. Their cross-rigid base belt and corrugated rubber sidewalls combine with a variety of different-sized cleats to ensure your material stays in place.

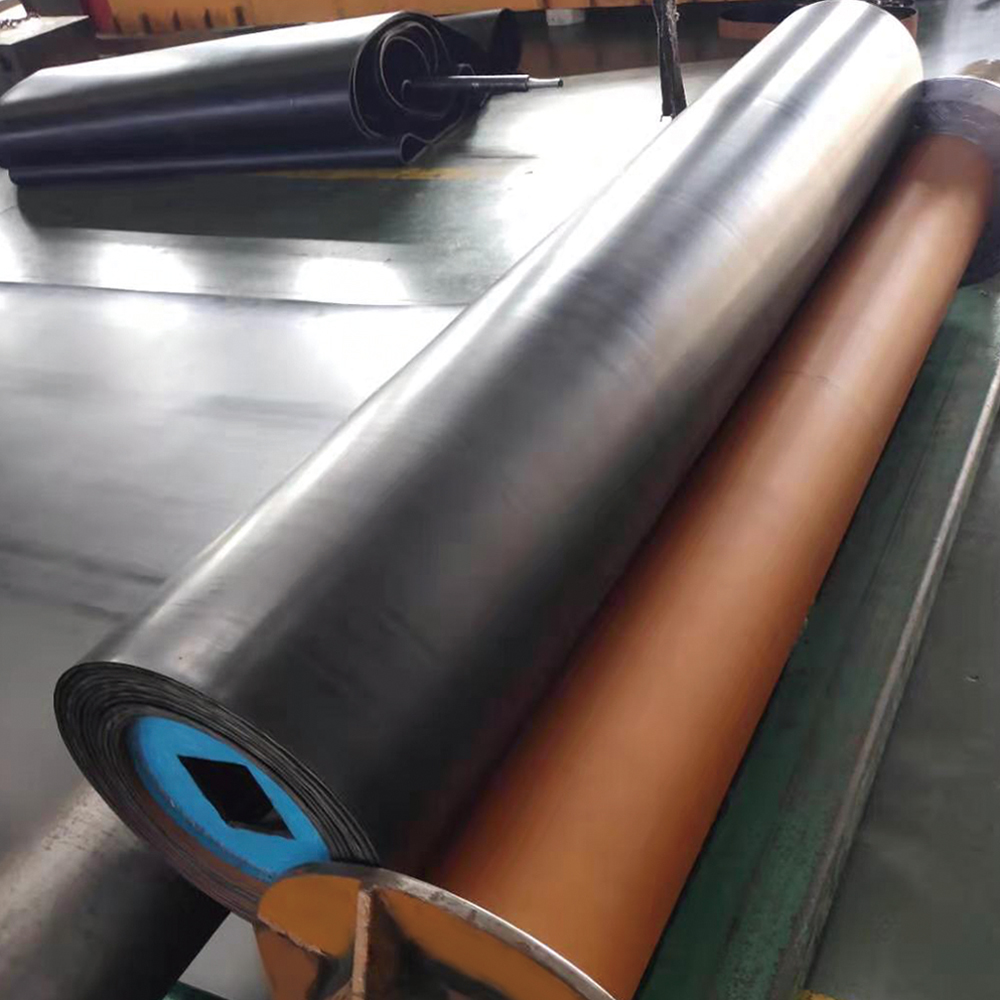

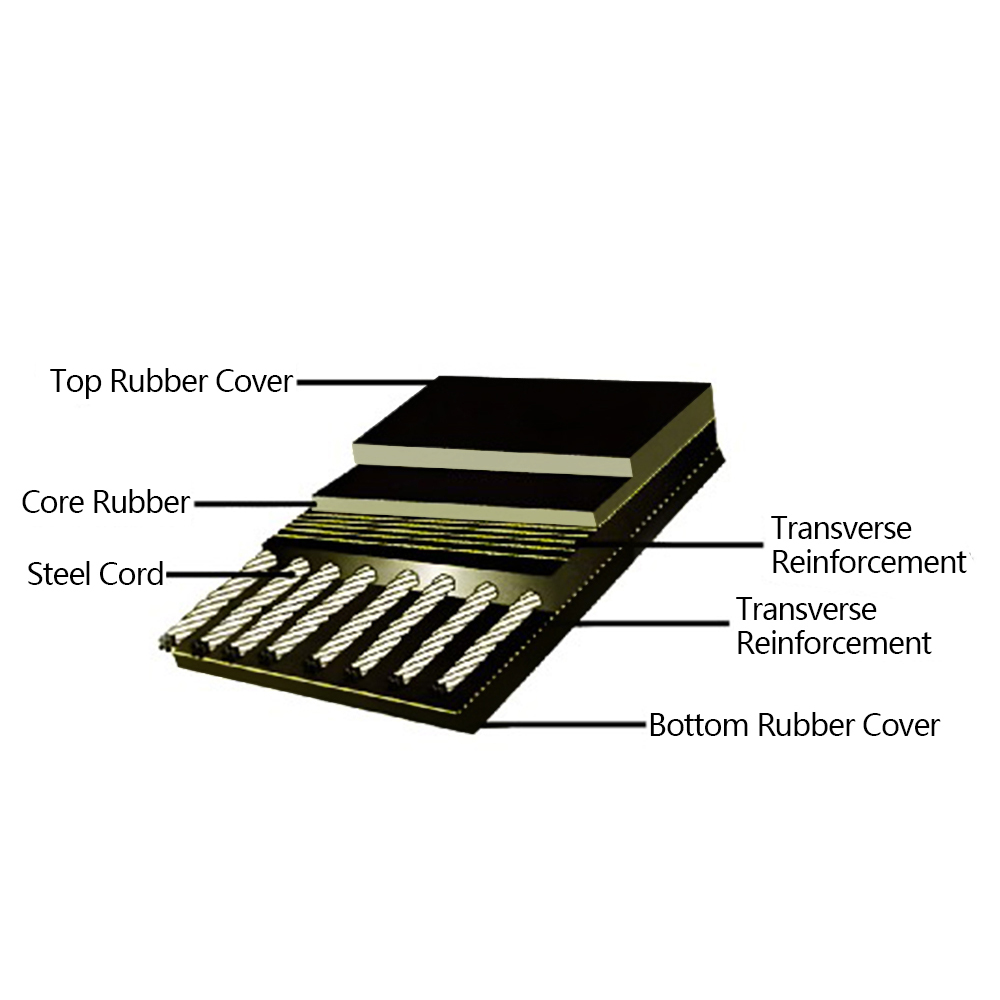

Base belt: The skeleton material adopts cotton-polyester impregnated canvas (EP canvas, steel cored) and horizontal rigid reinforcement layer;By adding a horizontal rigid reinforcement layer in the belt body, the problem of the collapse of the large-size sidewall belt is solved.

Sidewall: According to the function of the sidewall and the running characteristics of the belt as a whole, measures such as increasing the rubber content of the sidewall and adding nylon cloth as a skeleton layer inside the sidewall have been taken; The flexural and tearing resistance of the side guard has been enhanced, and the service life of the side guard has also been improved.

Cleat: The mixing process of rubber and fiber composite materials makes the separator have high toughness and hardness, which enhances its impact resistance and prevents it from deforming due to large stress.Base belt, sidewall, and cleat: The advanced process of secondary synchronous low-temperature continuous vulcanization is adopted, which improves the bonding strength and avoids the aging of the baseband caused by multiple high-temperature vulcanization.

The corrugated sidewall conveyor belt is composed of a transverse rigid special base belt sidewall cleat. Currently, the most advanced secondary vulcanization process is adopted,

which ensures the adhesion between the base belt and the sidewall cleat, and also endows it with the advantages of flex resistance, strong tensile strength and good wear resistance.

Sidewall conveyor belts