Performance of Rubber in Extremely Cold Environments and Suggestions for Performance Improvement

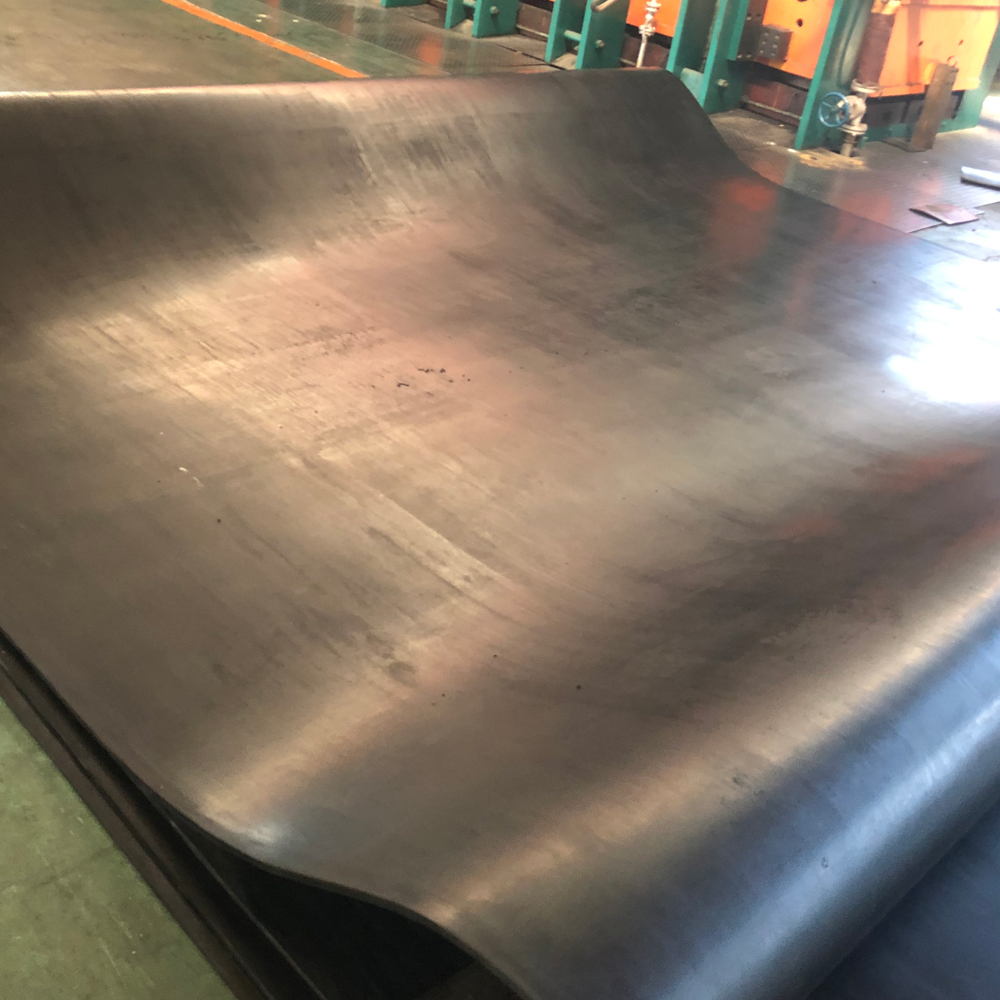

With the increasing demand for exploration and utilization of polar and plateau environments, rubber, as one of the important industrial materials, faces challenges in usage under even higher or lower temperature conditions. However, under extremely cold conditions, rubber can encounter several issues, such as hardening, embrittlement, reduced wear resistance, and decreased aging resistance, which affect its service life and safety. Therefore, research into improving its performance is of great significance.

1、Performance of Rubber under Extreme Cold Conditions Rubber, a polymeric elastic material, exhibits excellent elasticity and toughness under normal temperature conditions. However, under extreme cold conditions, rubber tends to solidify, harden, and become brittle. This largely relates to the effect of temperature on the mechanical state of the molecules. When the temperature drops below the glass transition temperature of the rubber, the rubber molecules can be considered bound and unable to freely extend and deform as they do at room temperature, causing the loss of elasticity and thus resulting in diminished performance of rubber products.

2、Suggestions for Improving Rubber Performance under Extreme Cold Conditions To enhance the performance of rubber under extreme cold conditions and reduce phenomena such as embrittlement and aging, improvements should be made in the following aspects:

Add low-temperature catalysts: Low-temperature catalysts are additives that chemically reduce the melting point of the molecular coating layer of rubber materials, lowering the glass transition temperature. During the preparation of rubber products, appropriately adding low-temperature catalysts to the raw materials can significantly expand the usable temperature range of rubber.

Add anti-aging agents: Anti-aging agents effectively prolong the service life of rubber materials and reduce the effects of oxidation, ultraviolet radiation, and chemical substances after environmental exposure. Adding certain antioxidants and UV absorbers to rubber products can improve their aging resistance and extend their lifespan.

Reduce vulcanization temperature: Vulcanization is an important process in rubber products and also a key factor affecting the performance of rubber under extreme cold conditions. Excessively high vulcanization temperatures or prolonged vulcanization times can alter the molecular structure and degrade mechanical properties. Appropriately reducing the vulcanization temperature to prevent over-vulcanization can significantly improve the service life and maintain the strength and toughness of rubber under extreme cold conditions.

In conclusion, to ensure the reliability and safety of rubber materials under extreme cold conditions, it is necessary to continuously optimize and improve their formulations and production processes, enhance compatibility, ensure correct selection of raw materials, and strictly control variations in quality, temperature, and pressure during processing, thereby ensuring the performance of rubber products under extreme cold conditions.

The structure, process and mai

The structure, process and mai

The Principles and Process of

The Principles and Process of

Performance of Rubber in Extre

Performance of Rubber in Extre

The application fields of rubb

The application fields of rubb