The structure, process and maintenance of rubber conveyor belts

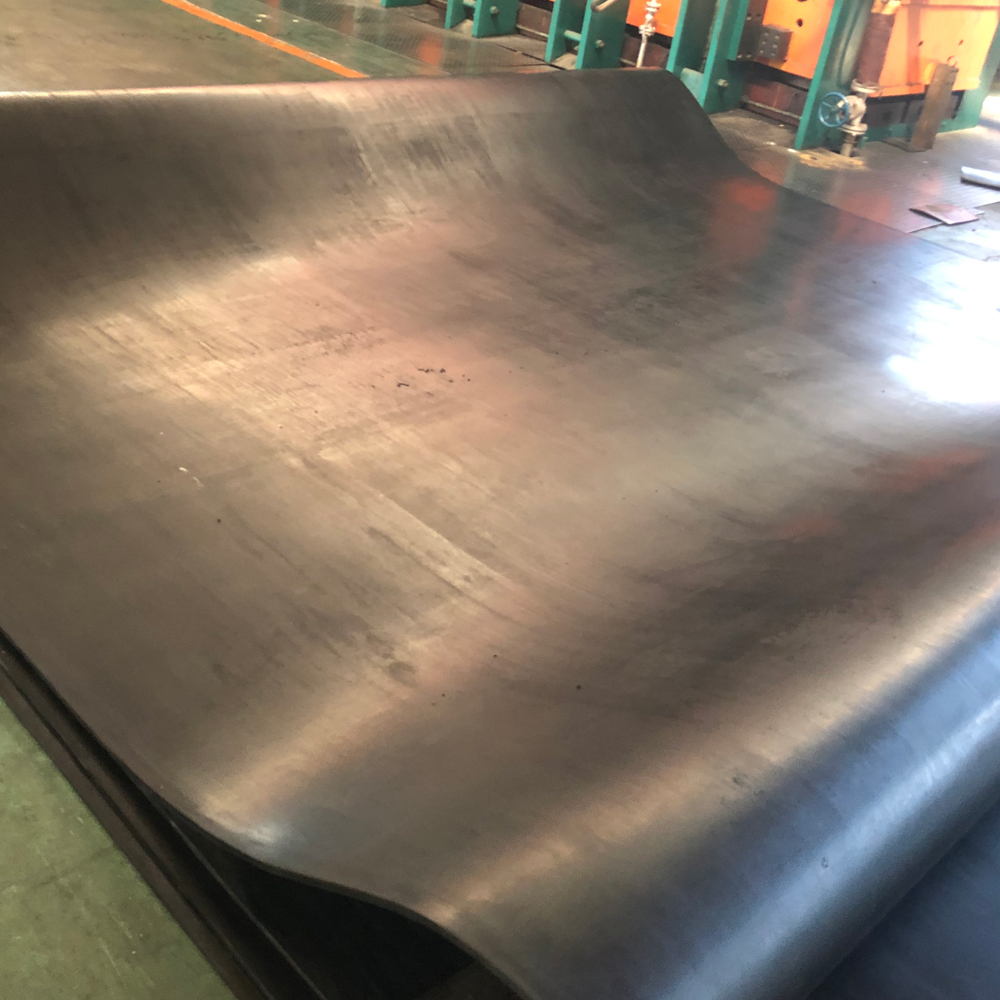

Rubber conveyor belts are widely used conveying equipment in industries such as mining, ports, power, and chemical engineering. They feature a simple structure, reliable operation, and large conveying capacity, and are extensively applied in the transportation of various materials. This article will provide a detailed introduction to the structure, materials, manufacturing process, and maintenance of rubber conveyor belts.

1、 Structure of Rubber Conveyor Belts

Rubber conveyor belts are mainly composed of rubber belt bodies, belt cores, covering layers, side belts, joints, etc. Among them, the rubber belt body is the main part of the conveyor belt. It is composed of multiple layers of fiber fabric and rubber, and has good strength and elasticity. The core of the belt is the skeleton part of the conveyor belt. It is usually made of steel wire rope or steel belt and is used to support the weight of the conveyor belt and withstand tensile force. The covering layer is the working surface of the conveyor belt. It is usually composed of rubber and other materials and is used to protect the belt body and increase the coefficient of friction. The side belt is the side of the conveyor belt. It is usually made of rubber and other materials and is used to protect the belt body and prevent materials from overflowing. The joint is the connecting part of the conveyor belt, which is usually connected by metal clamps or cold joint adhesives, etc.

2、Materials of Rubber Conveyor Belts

The materials of rubber conveyor belts mainly include rubber, fiber fabrics, steel wire ropes, steel belts, etc. Among them, rubber is the main material of conveyor belts, which has good elasticity, wear resistance, corrosion resistance and other characteristics. Fiber fabric is the main reinforcing material for conveyor belts. It is usually made of materials such as polyester, nylon and cotton, and has good strength and wear resistance. Steel wire ropes and steel belts are the main reinforcing materials of conveyor belts. They feature high strength, wear resistance and other characteristics, and can withstand considerable tensile force and weight.

3、 Manufacturing Process of Rubber Conveyor Belts

The manufacturing process of rubber conveyor belts mainly includes rubber mixing, core manufacturing, belt body manufacturing, covering layer manufacturing, side belt manufacturing, joint manufacturing and other links. Among them, rubber mixing is a key link in the manufacturing of conveyor belts, which determines the quality and performance of the conveyor belts. The core of the conveyor belt is the skeleton part, which is usually made of steel wire rope or steel belt and needs to go through processes such as drawing and stranding. The belt manufacturing is the main part of the conveyor belt. It is composed of multiple layers of fiber fabrics and rubber, and needs to undergo processes such as calendering and vulcanization. The covering layer manufacturing is the working surface of the conveyor belt, which is usually composed of rubber and other materials and needs to undergo processes such as calendering and vulcanization. Side belt manufacturing refers to the side of the conveyor belt. It is usually composed of rubber and other materials and needs to undergo processes such as calendering and vulcanization. Joint manufacturing is the connecting part of the conveyor belt. It is usually connected by metal clamping plates or cold bonding adhesives, etc., and needs to go through processes such as cutting, drilling, and crimping.

4、 Maintenance and Care of Rubber Conveyor Belts

The maintenance and care of rubber conveyor belts are the key to ensuring their normal operation and extending their service life. Specific measures include:

Regularly inspect the wear of the conveyor belt and replace the severely worn parts in a timely manner.

Regularly clean the working and side surfaces of the conveyor belt to prevent material adhesion and accumulation.

Regularly check the tension and alignment of the conveyor belt, and make timely adjustments and corrections.

Regularly lubricate the rollers and bearings of the conveyor belt to ensure its normal operation.

Regularly inspect the joints and side bands of the conveyor belt, and repair or replace them in a timely manner.

In conclusion, rubber conveyor belts are an important conveying equipment, and their quality and performance directly affect production efficiency and product quality. Therefore, we should enhance the research and development of rubber conveyor belts, continuously improve their quality and performance, and at the same time strengthen their maintenance and care to extend their service life, making greater contributions to industrial production.

The structure, process and mai

The structure, process and mai

The Principles and Process of

The Principles and Process of

Performance of Rubber in Extre

Performance of Rubber in Extre

The application fields of rubb

The application fields of rubb