The Principles and Process of Rubber Compounding

The rubber compounding technology is a crucial aspect of the rubber industry. It involves uniformly mixing rubber raw materials with various additives, which is a key step in producing different kinds of rubber products. This article will provide an introduction to the principles, processes, equipment, and common issues related to rubber compounding.I. Principles of Rubber Compounding

Rubber compounding works by uniformly mixing rubber raw materials with various additives to create a homogeneous mixture for subsequent processing and forming. The goal of rubber compounding is to thoroughly blend the rubber raw materials with additives, ensuring a uniform mixture suitable for further processing and shaping. During the compounding process, parameters such as compounding temperature, time, and speed must be controlled to ensure compounding quality.II. Process Flow of Rubber Compounding

The general steps in the rubber compounding process are as follows:

1、Pre-treatment of rubber raw materials: The rubber raw materials are cut, sifted, and dried for subsequent compounding.

2、Preparation of additives: Based on the requirements of the rubber product, various additives are proportionally prepared according to specific formulations.

3、Compounding: The rubber raw materials and additives are placed into a compounding machine for thorough mixing. During this process, compounding temperature, time, and speed are monitored to ensure high-quality results.

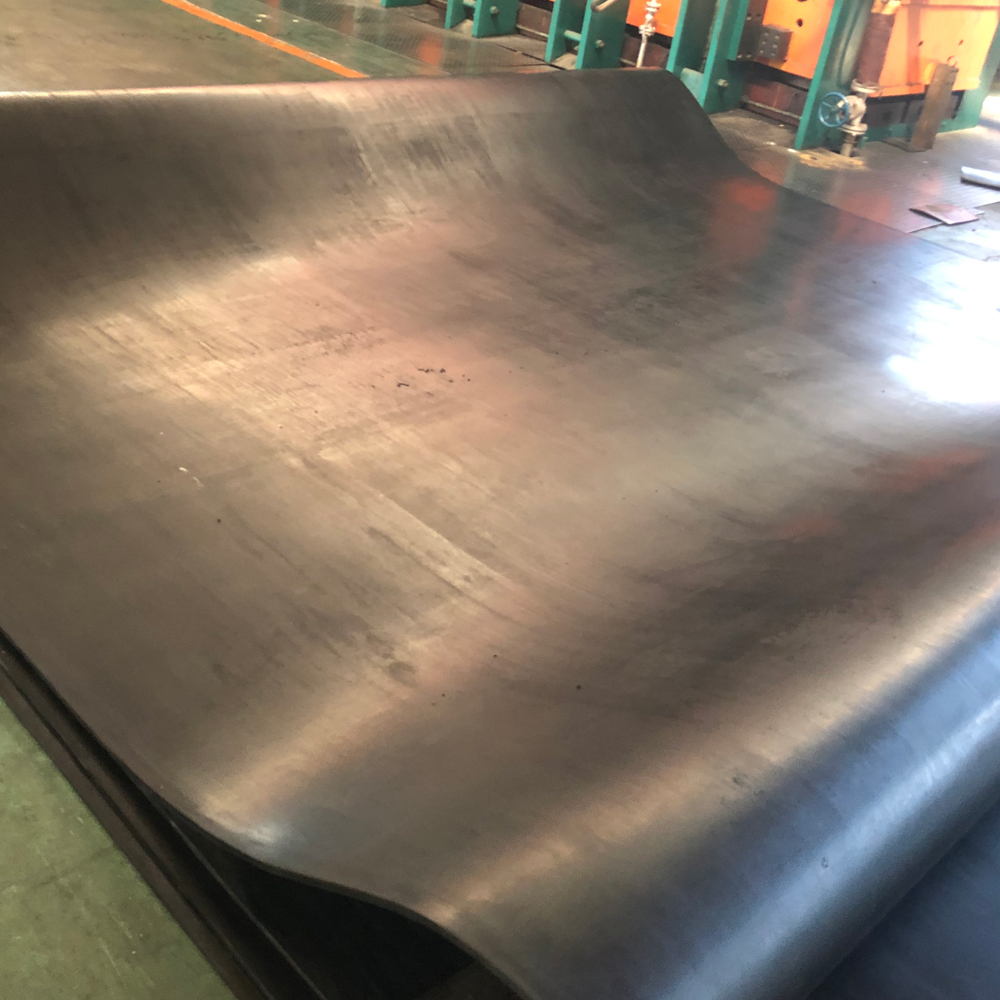

4、Discharge: After compounding is completed, the compounded rubber mixture is removed from the machine for further processing and shaping.

Equipment Used in Rubber Compounding

There are two main types of equipment used in rubber compounding: open-type mixers and closed-type mixers.

1、Open-Type Mixers: These are commonly used compounding machines known for their simple operation, easy maintenance, and effective mixing performance. They generally come in horizontal and vertical configurations.

2、Closed-Type Mixers: These are efficient, energy-saving, and environmentally friendly compounding machines.

Their advantage lies in the fact that water or steam is not required during the compounding process, thereby reducing energy consumption and environmental impact. Closed-type mixers typically include internal-turning and external-turning types.

Common Issues in Rubber Compounding

1、Excessively high or low compounding temperatures: Too high a temperature may lead to rubber aging and deterioration, while too low a temperature may prolong compounding time and reduce effectiveness.

2、Overly long or short compounding times: Extended times can cause aging and degradation of the rubber, while insufficient times may result in poor mixing outcomes.

3、Compounding speeds that are too fast or too slow: Excessively fast speeds may accelerate rubber aging and deterioration, whereas overly slow speeds may reduce compounding effectiveness.

4、Improper additive ratios: Unbalanced additive proportions may lead to unstable properties in the rubber mixture, negatively affecting the quality of the final product.

In conclusion, rubber compounding technology plays a vital role in the rubber industry, directly influencing the quality and performance of rubber products. Throughout the compounding process, controlling parameters such as temperature, time, and mixing speed is essential to achieving optimal results. Additionally, careful selection and regular maintenance of compounding equipment are necessary to ensure both efficiency and production quality.

The structure, process and mai

The structure, process and mai

The Principles and Process of

The Principles and Process of

Performance of Rubber in Extre

Performance of Rubber in Extre

The application fields of rubb

The application fields of rubb