What are the technical parameters that affect the rubber liner of a ball mill?

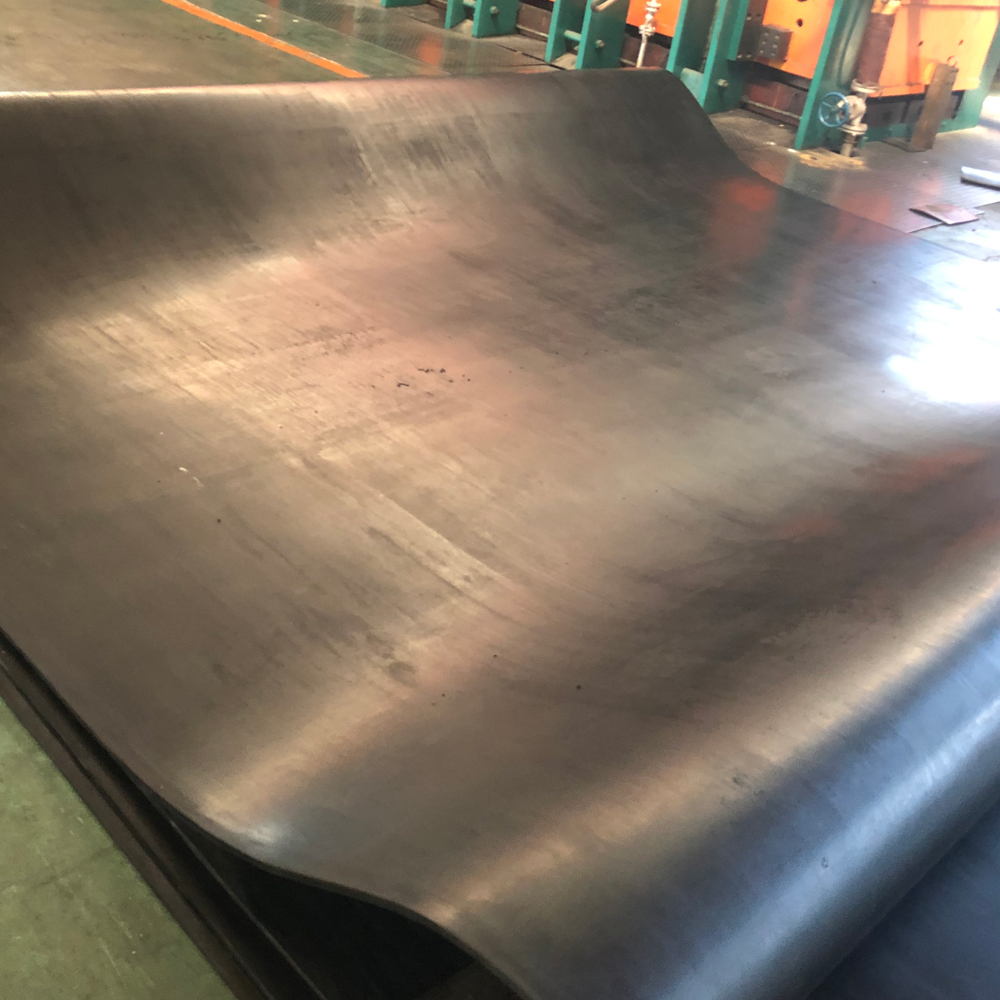

The technical parameters of rubber linings include the following aspects:

Rubber hardness: The hardness of rubber linings is usually between 60 and 90 degrees. The higher the hardness, the better the wear resistance, but the poorer the elasticity.

Rubber thickness: The thickness of the rubber lining is usually between 20 and 50mm. The greater the thickness, the better the wear resistance, but it will have a certain impact on the volume and grinding efficiency of the ball mill.

Rubber material: The material of rubber lining is usually natural rubber, synthetic rubber or butyl rubber, etc. Rubber of different materials has different wear resistance and corrosion resistance. Rubber density: The density of rubber lining is usually between 1.2 and 1.5g/cm³. The higher the density, the better the wear resistance, but it will have a certain impact on the volume and grinding efficiency of the ball mill.

Rubber vulcanization: Rubber linings need to undergo vulcanization treatment. The vulcanization time and temperature will affect the performance and wear resistance of the rubber.

The above are some common technical parameters of rubber linings. Different ball mills and grinding materials require the selection of suitable rubber lining parameters.

The structure, process and mai

The structure, process and mai

The Principles and Process of

The Principles and Process of

Performance of Rubber in Extre

Performance of Rubber in Extre

The application fields of rubb

The application fields of rubb