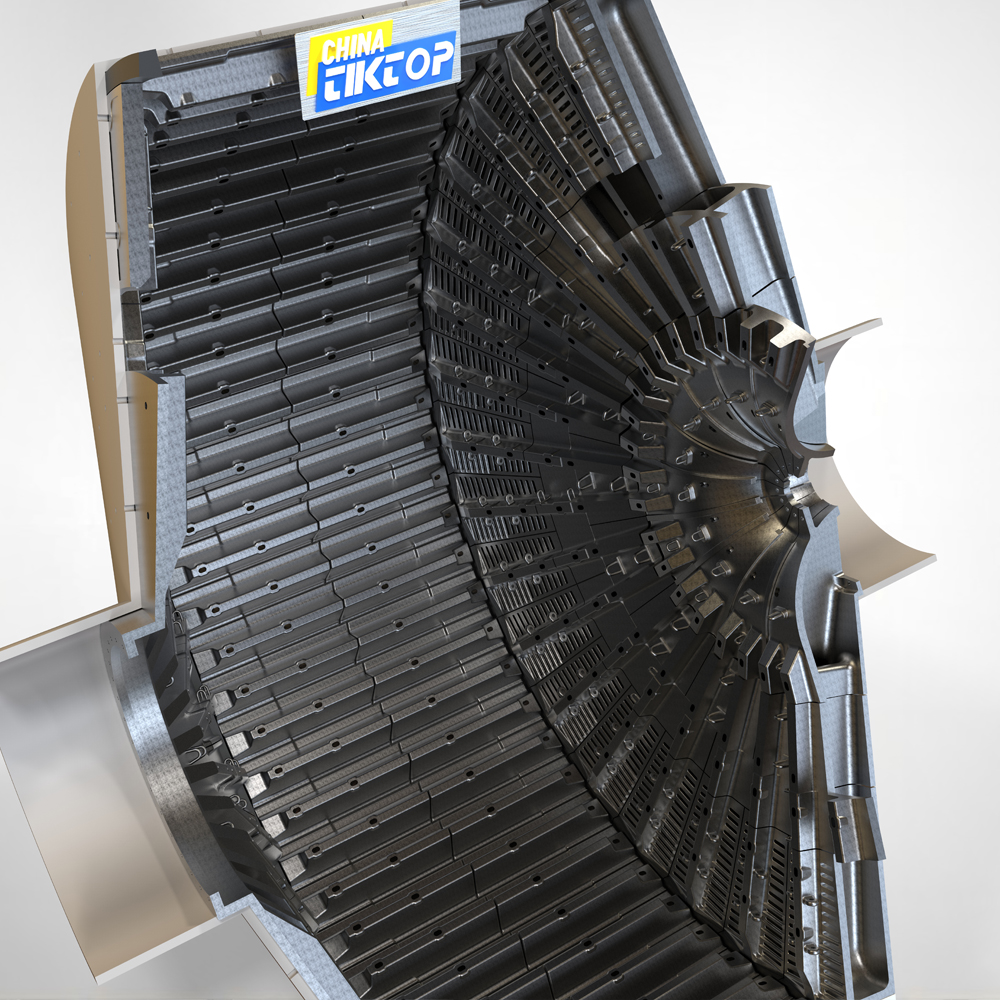

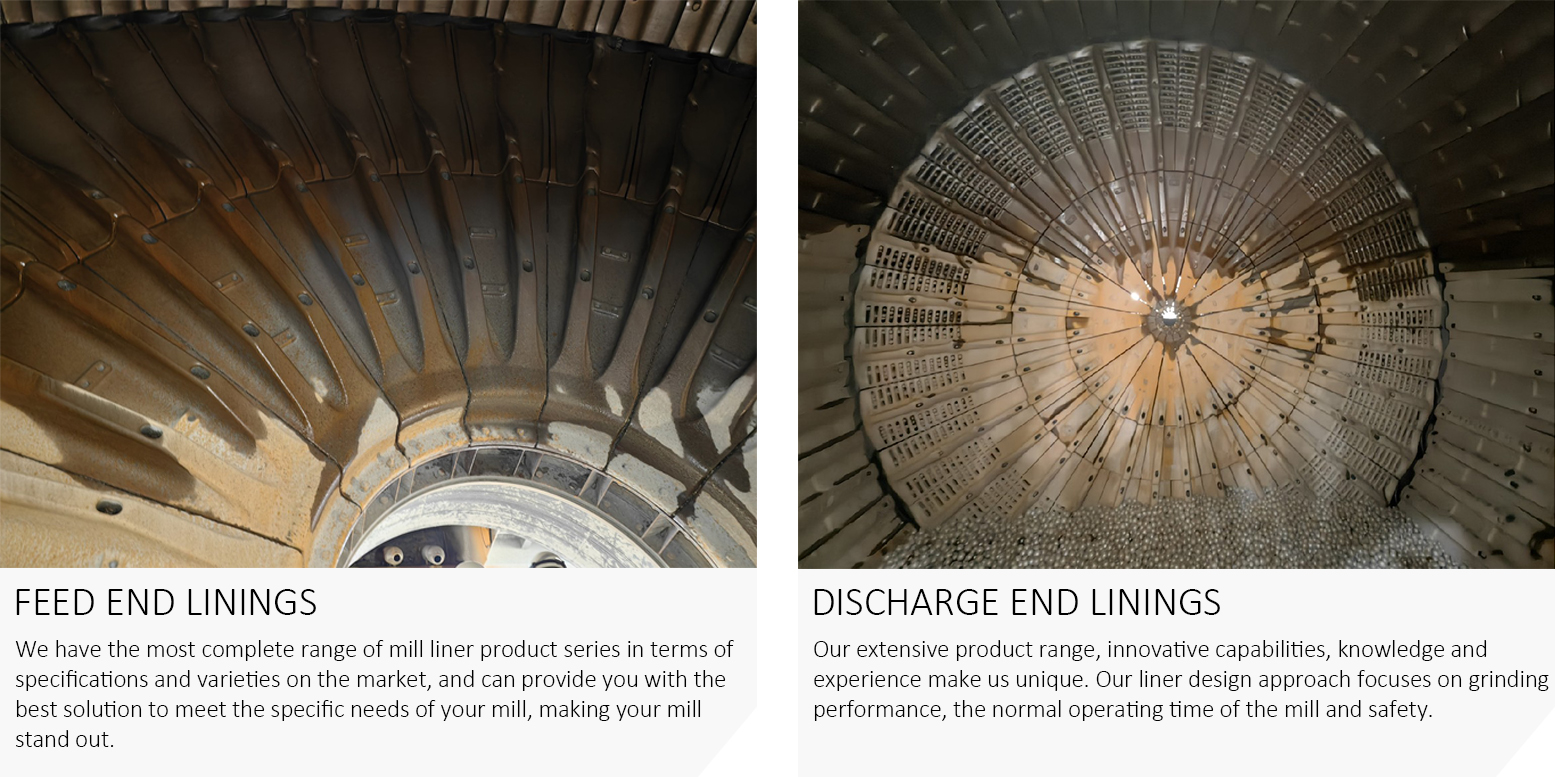

SAG Mill linings

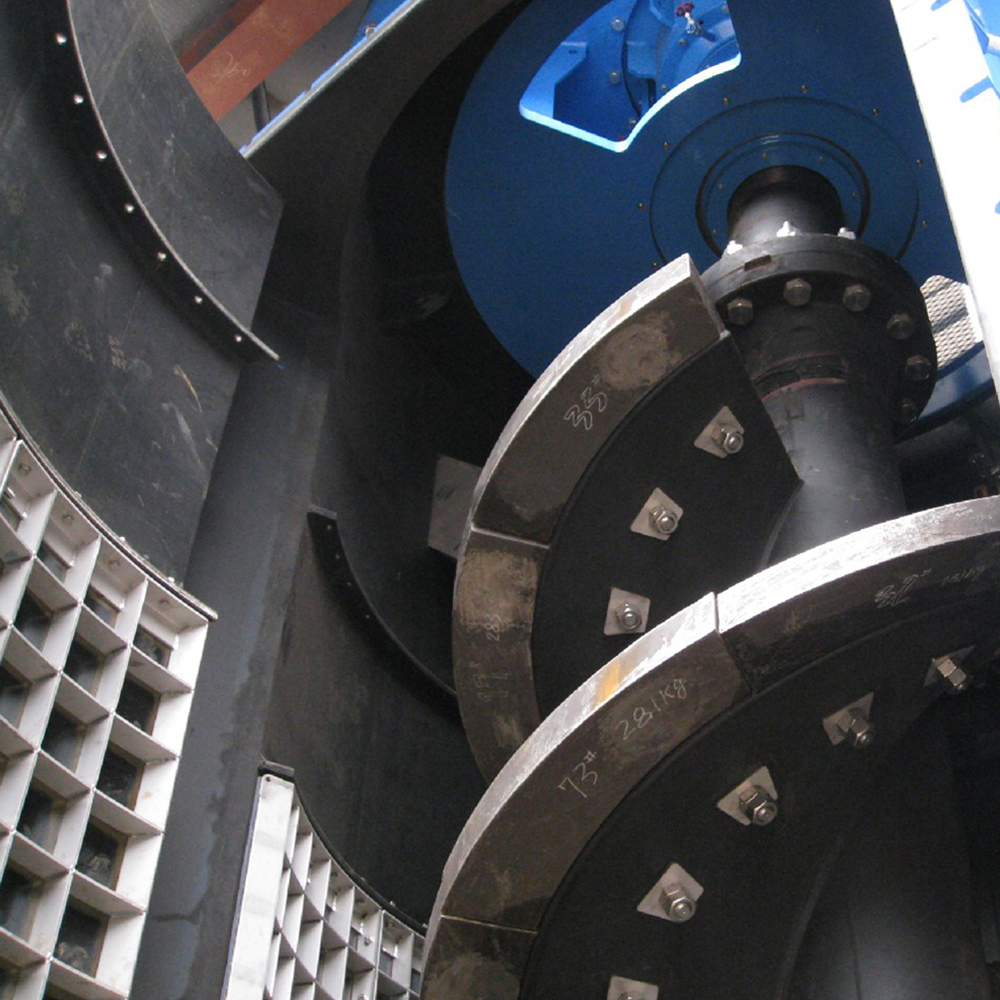

At TIKTOP, safety has always been the top priority we pay more attention to when designing vulnerable parts. We are deeply aware that safety is the foundation of all production activities. Any minor oversight may lead to serious consequences.

During the design process, we fully considered all possible risks and ensured the safety of vulnerable parts during use by optimizing the structure and choosing appropriate materials.

In addition, we also provide clear guidance for the installation process by setting up guiding marks and other means to ensure that operators can install correctly and safely. In conclusion, through various measures, we strive to provide customers with safe and reliable wear parts products to ensure the smooth progress of production activities.

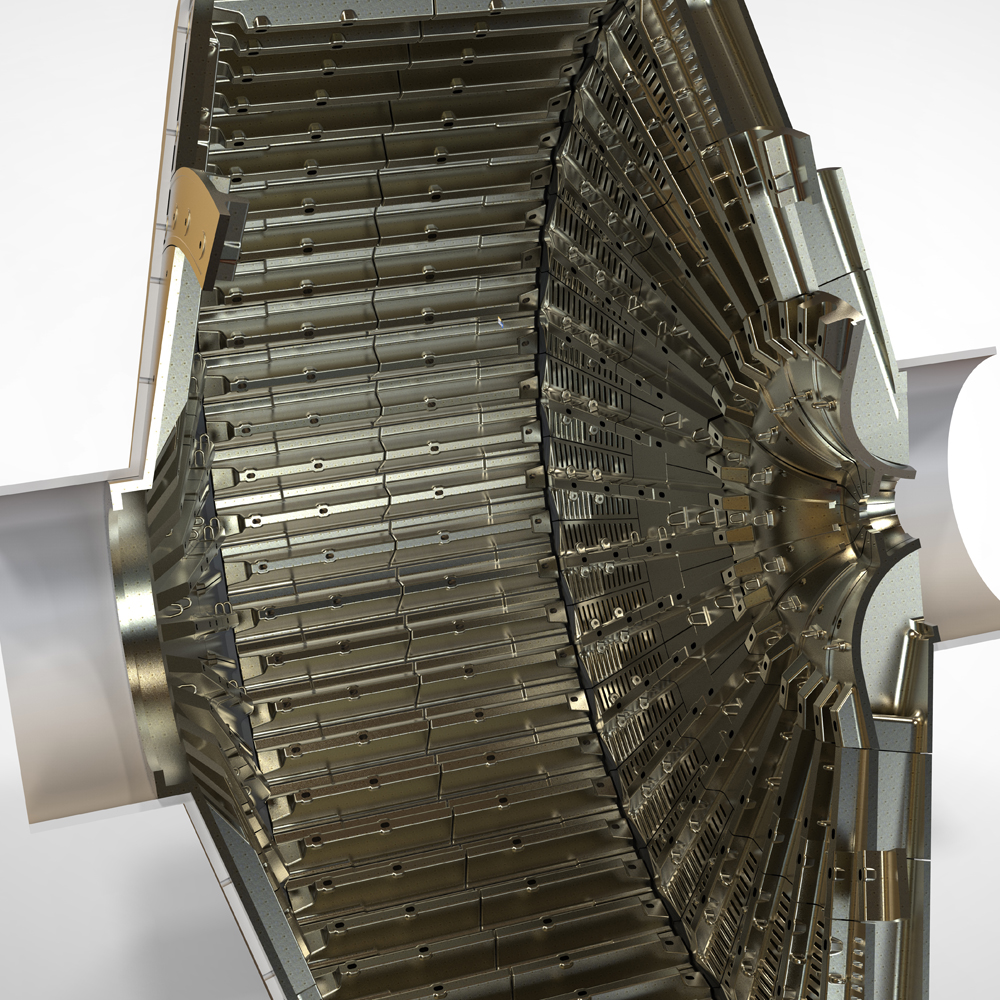

At TIKTOP, we have an unwavering pursuit of product quality. All of our metal mill liners are meticulously produced in our own foundry. We are well aware that high-quality raw materials are the foundation for creating outstanding products. For this reason, we have specially developed chromium-molybdenum steel suitable for the application of mill liners. This kind of steel has undergone strict screening and testing, and is carefully selected based on the unique operating conditions of each mill to ensure that it can perform at its best in various harsh working environments.

Our foundry has always adhered to high standards and strict requirements throughout the entire production process. At every stage from research and development to design and production, we implement a strict quality assurance plan. During the research stage, our professional team delves deeply into the properties and applications of materials, providing a solid theoretical foundation for product development.

At TIKTOP, we have an unwavering pursuit of product quality. All of our metal mill liners are meticulously produced in our own foundry. We are well aware that high-quality raw materials are the foundation for creating outstanding products. For this reason, we have specially developed chromium-molybdenum steel suitable for the application of mill liners. This kind of steel has undergone strict screening and testing, and is carefully selected based on the unique operating conditions of each mill to ensure that it can perform at its best in various harsh working environments.

Our foundry has always adhered to high standards and strict requirements throughout the entire production process. At every stage from research and development to design and production, we implement a strict quality assurance plan. During the research stage, our professional team delves deeply into the properties and applications of materials, providing a solid theoretical foundation for product development.