Ball Mill Rubber Linings

Ball Mill Rubber Linings

In mining production, the importance of mill liners cannot be ignored. It undertakes the crucial task of protecting the equipment, just like a loyal guard, defending the mill against all kinds of wear and impact. Meanwhile, the grinding mill liner has a significant impact on the performance of the grinding mill. A high-quality grinding mill liner can significantly enhance the working efficiency and stability of the grinding mill, bringing numerous benefits to the production process.

TIKTOP's rubber mill liners have numerous advantages. First of all, it can offer customers a longer wear and tear life. After meticulous design and strict testing, this rubber liner plate features outstanding wear resistance and can maintain good.

In mining production, a good working environment is of vital importance for improving work efficiency and ensuring the health of employees. Our rubber mill liners have many significant advantages. First of all, rubber components have the characteristic of being lightweight. This feature makes them very safe and easy to handle during installation, replacement and daily operation.

Secondly, rubber liners perform exceptionally well in reducing noise. During the operation of the grinding mill, noise is often a disturbing problem. Our rubber liners are like silent guardians, functioning as shock absorbers and noise filters.

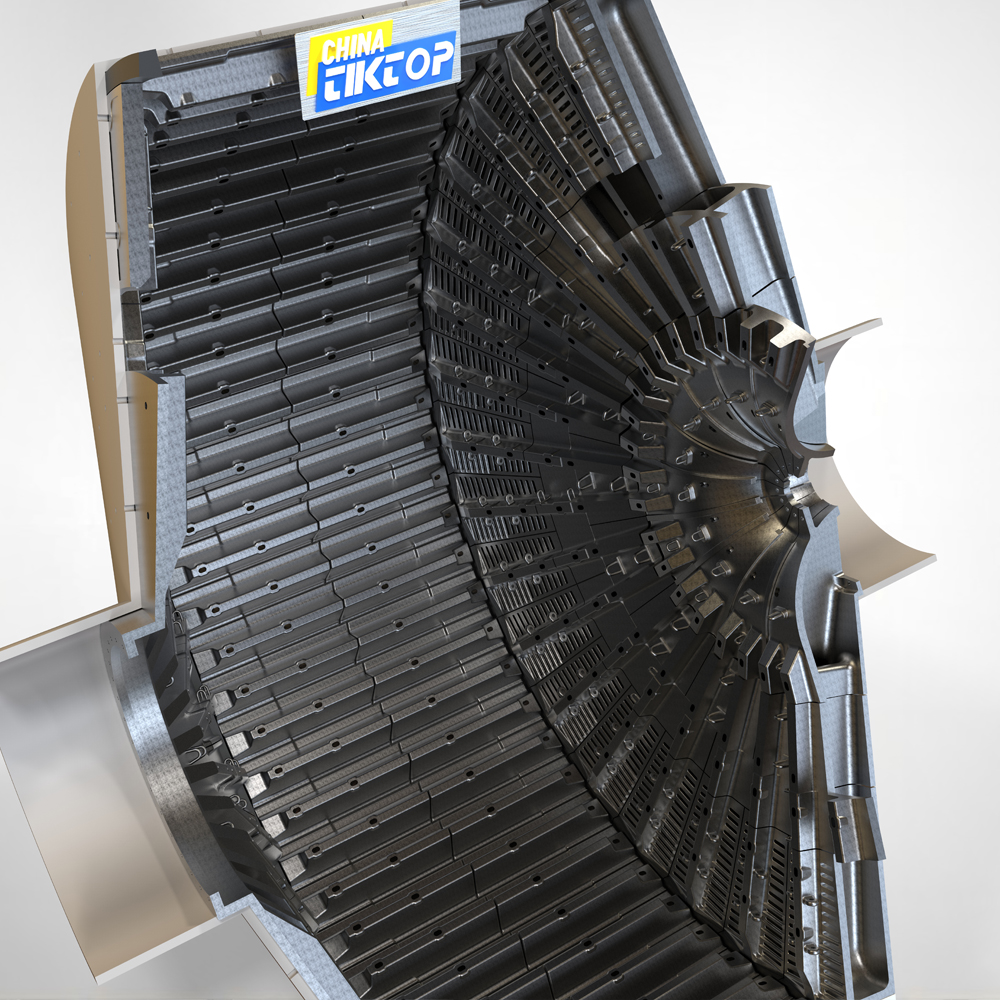

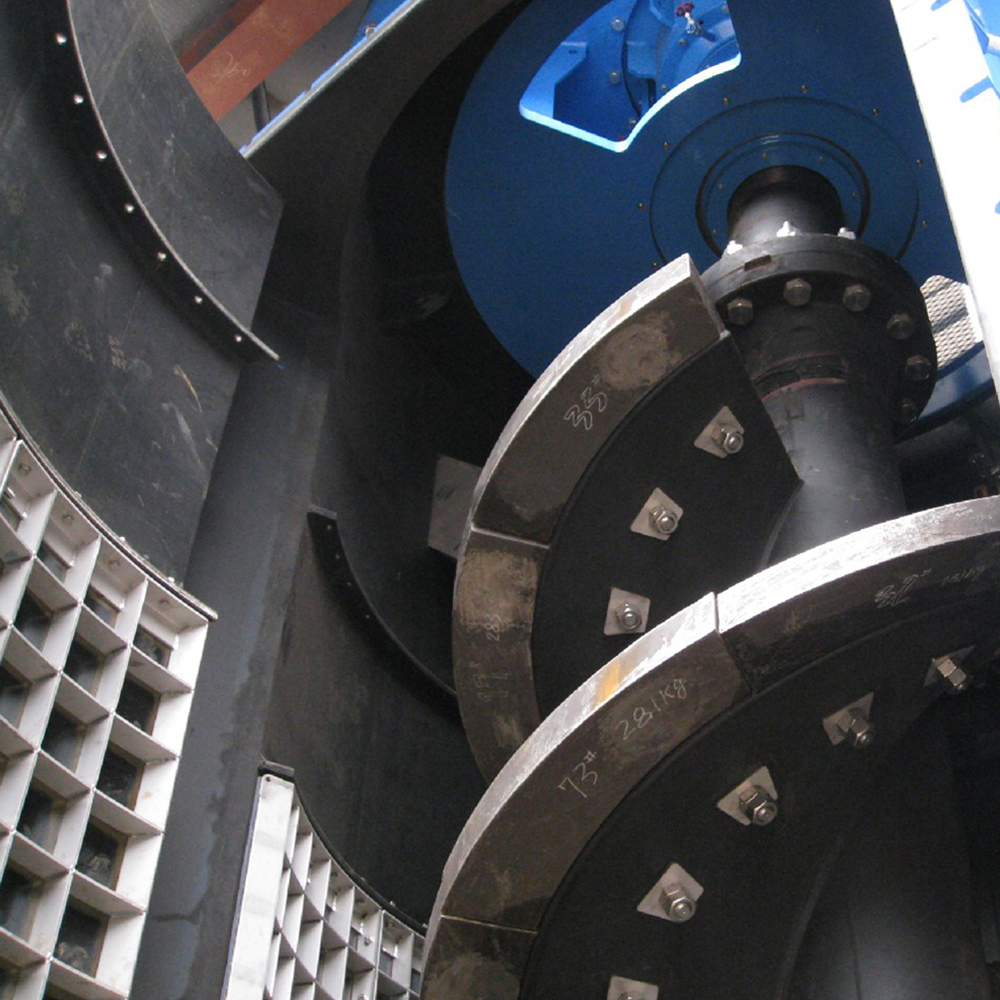

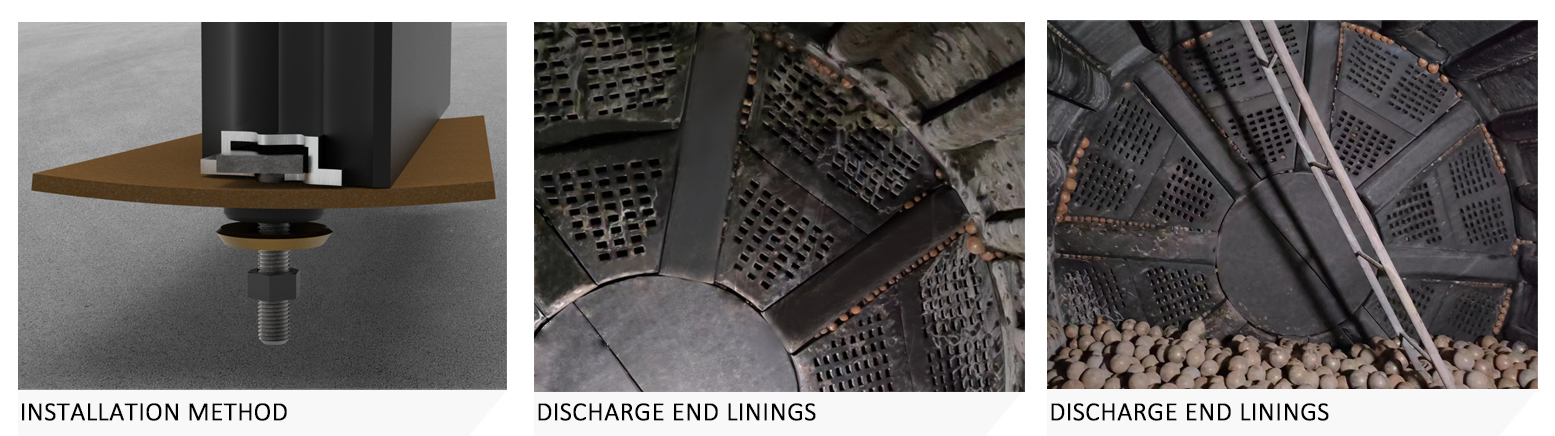

The ball mill is a key equipment for re-grinding materials after crushing. Its process involves mixing and grinding materials with a certain number of steel balls. The rubber liners of this type of equipment mainly consist of: head rubber liners and lift bar, center rings, filling strips, shell rubber liners and lift bar, manhole door liners and matching fasteners. They are made of highly wear-resistant rubber. It has the advantages of impact resistance, corrosion resistance, high wear resistance, low noise and easy replacement.

This product includes high-wear-resistant rubber liners for overflow type, grate type and multi-chamber type ball mills, which can meet the process requirements of first stage rough grinding, second stage or re-grinding. The product has been widely used in non-ferrous mines, chemical industry, desulfurization in power plants, alumina, new building materials and other projects. The main specifications range from 900 to 6800, with no limit on length.