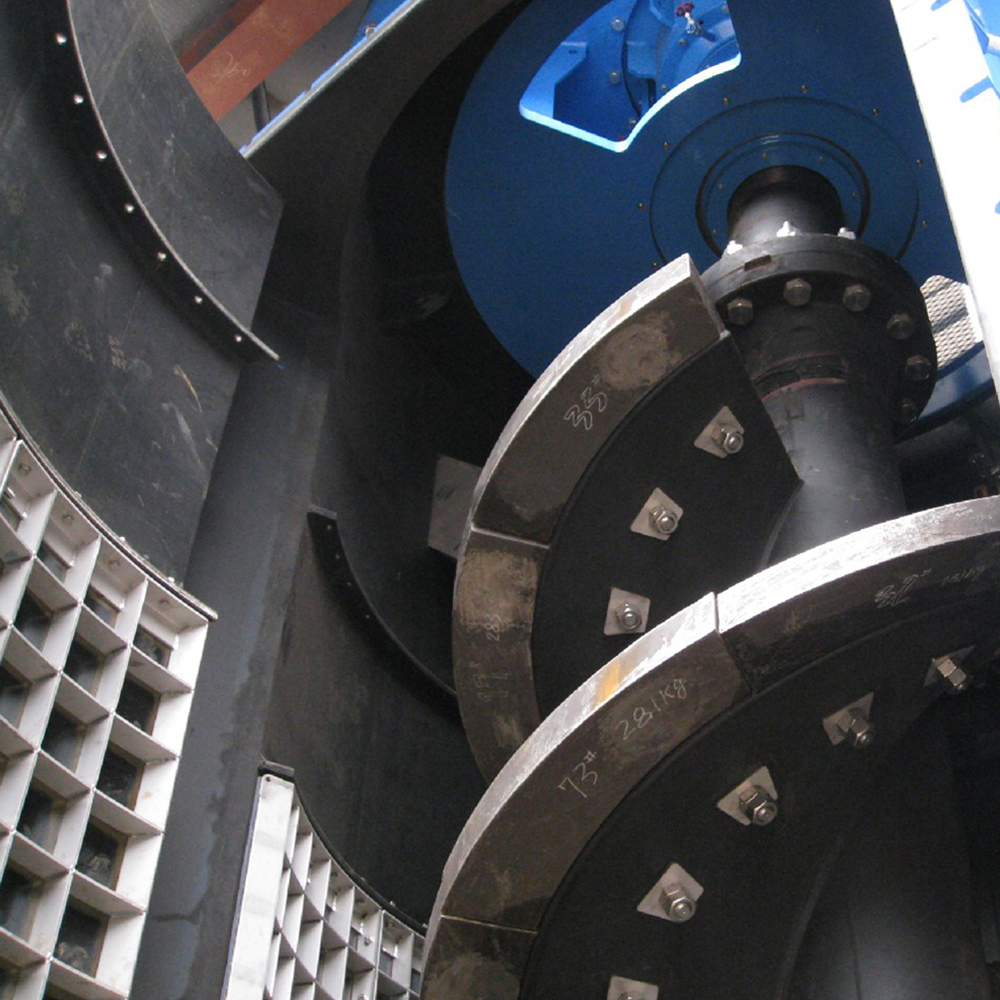

Tower Mill Linings

To ensure that the tower mill can continuously and stably perform at its best, we have provided a comprehensive set of solutions. We not only offer a full range of liners, but also various spare parts and consumables, providing all-round protection for tower mills and optimizing their grinding efficiency.

Our liners are high-quality products that have been carefully designed and manufactured. In terms of material selection, we have adopted carefully chosen wear-resistant alloys. These alloys have undergone rigorous testing and screening, and possess outstanding wear resistance and corrosion resistance, enabling them to maintain good performance for long periods in harsh working environments.

Whether it is installing liners or replacing spare parts and consumables, we have professional technicians to provide guidance to customers. We are well aware that safety is the cornerstone of enterprise production. Only under the premise of safety can efficient production and sustainable development be achieved.

Tower mill offers an energy efficient and reliable grinding technology that maximizes productivity and profitability.

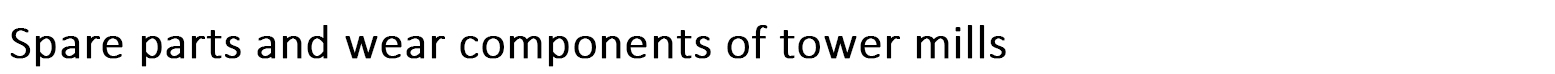

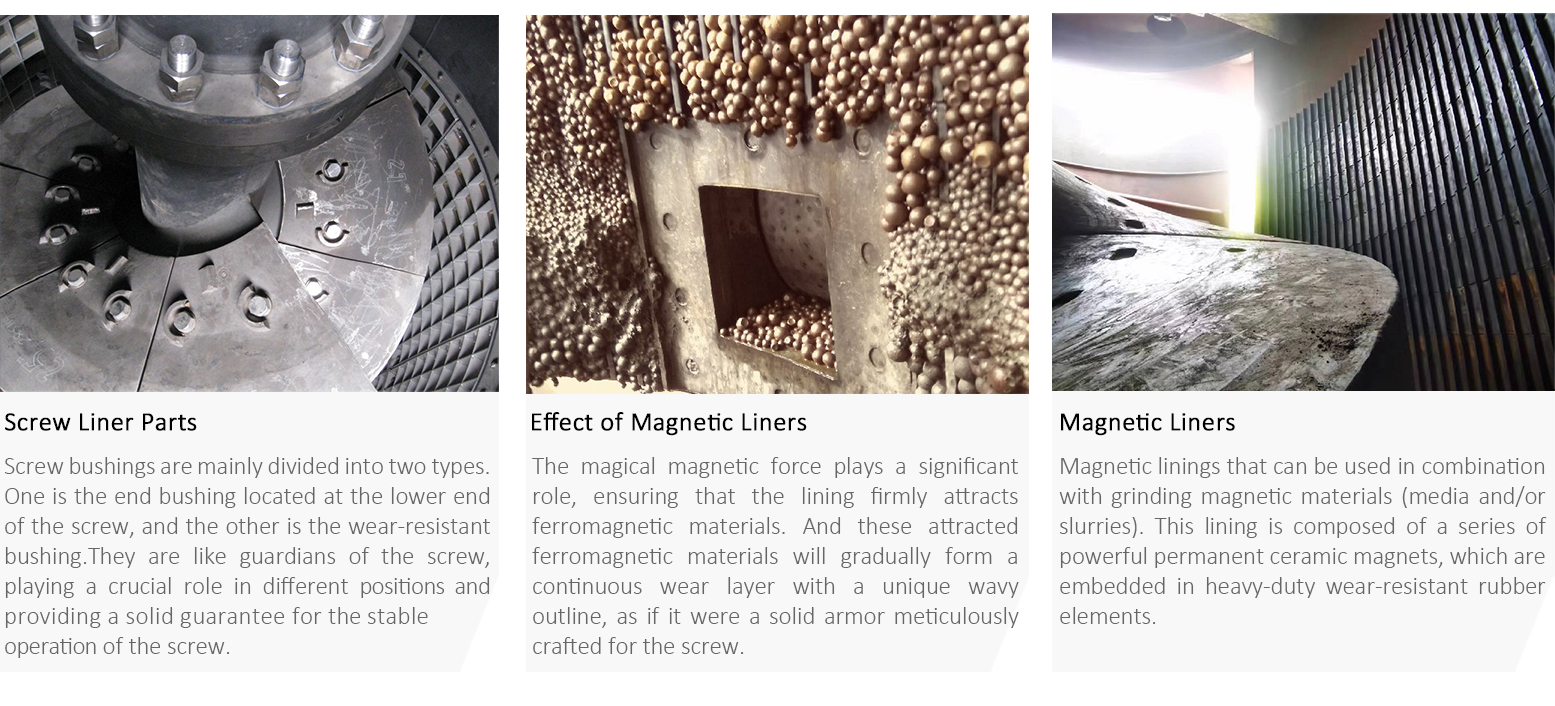

TIKTOP spare and wear parts provide longer wear life and keep your operations up and running even in the most challenging conditions.

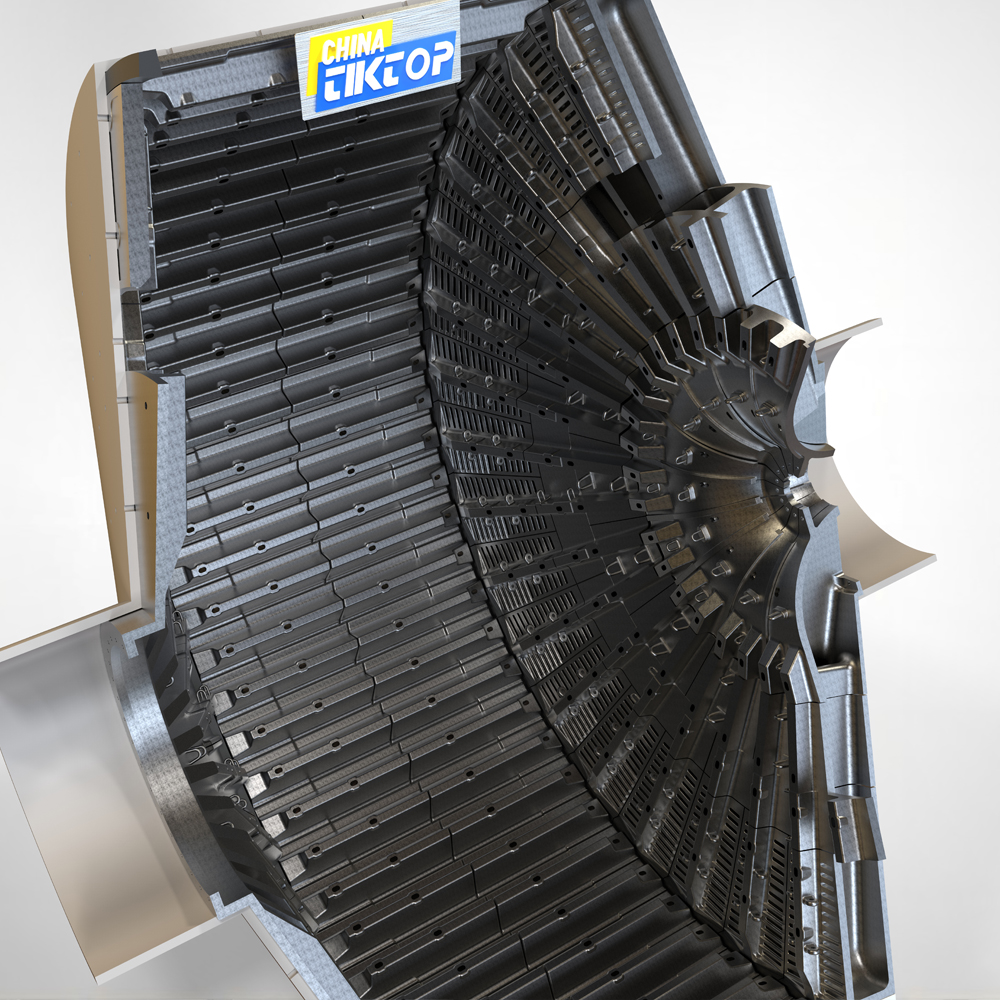

A mill lining is a customized wear part. Identifying the appropriate type of lining and design is vital for optimizing mill throughput and total grinding costs, including costs for energy, grinding media and maintenance. Furthermore, the design must be constantly optimized to meet your needs. We work closely with our customers and carefully follow their process to make sure the lining we supply is always optimized for current operating conditions.

We offers mill linings with materials and designs optimized for each specific application. We can design and supply mill linings for all types of mills - for own mills as well as for competitor mills - and for all parts of the mill. Our wide product range, innovations, knowledge and experience makes us unique. Our approach to lining design is focused on grinding performance, mill uptime and safety/sustainability.