Horizontal Centrifugal Slurry Pump

Slurry handling is vital in maximizing minerals processing plant’s productivity and efficiency. It plays a key role in mining processes involving water and other liquids.When you run pumps in your processes, you may face reoccurring challenges. These can include higher-than-expected wear rates, turbulence, leaks, and issues getting the right parts on time and getting the right expertise when needed. Although pumps may be a small part of your process, they must work reliably to ensure your operations run smoothly.

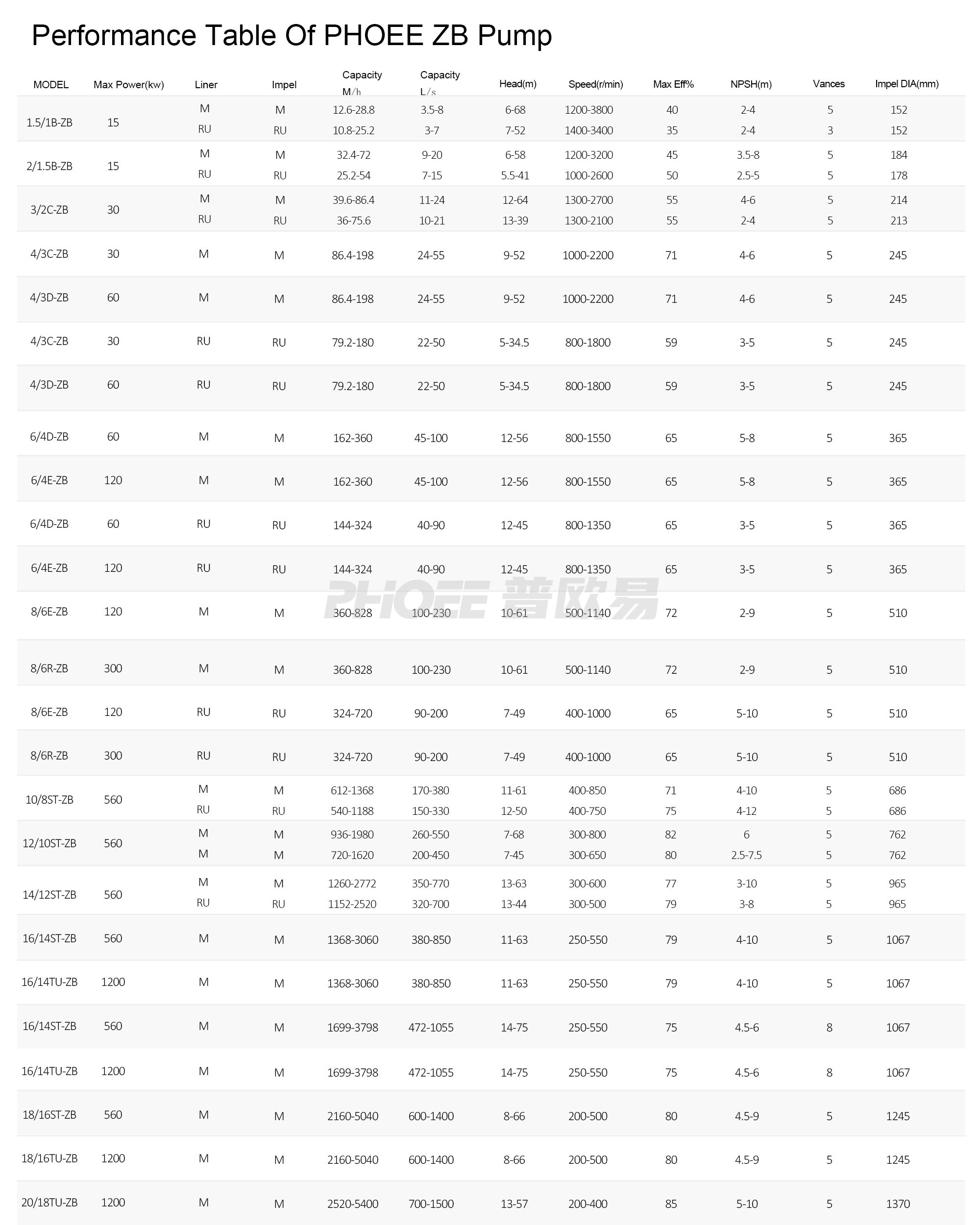

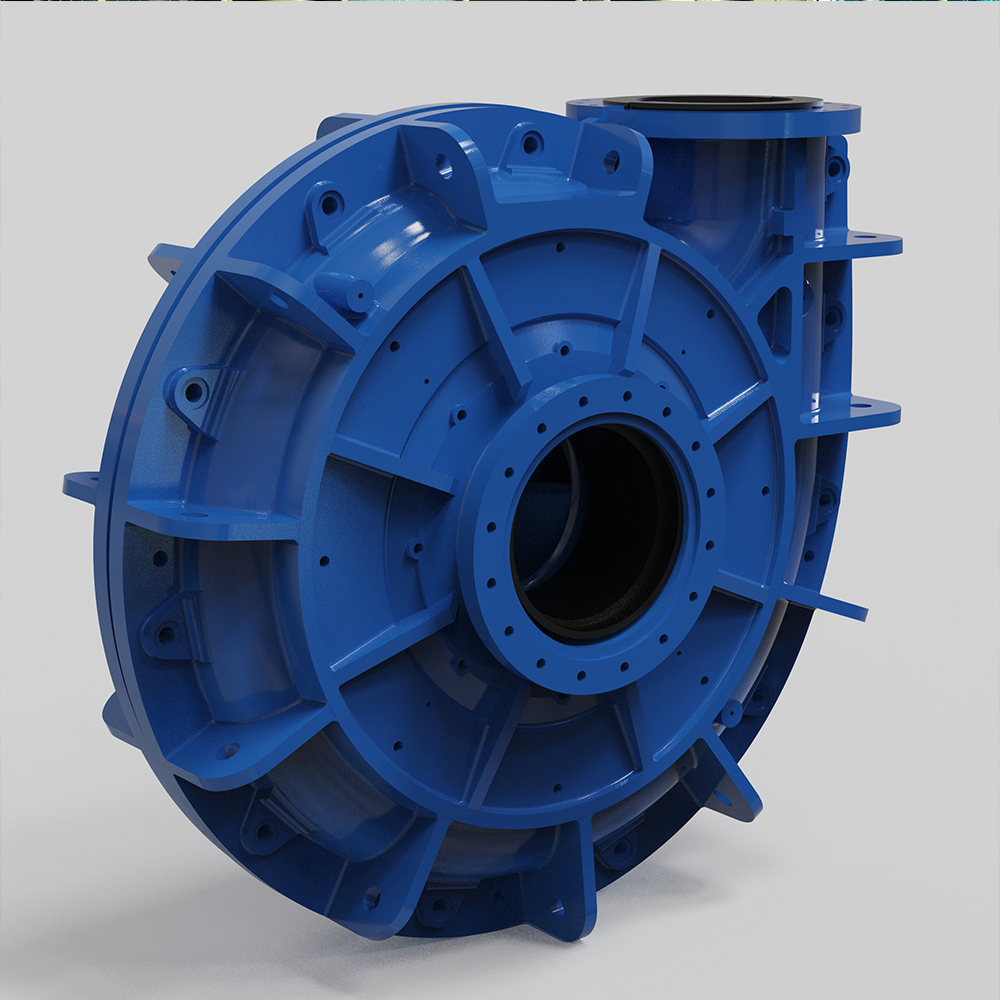

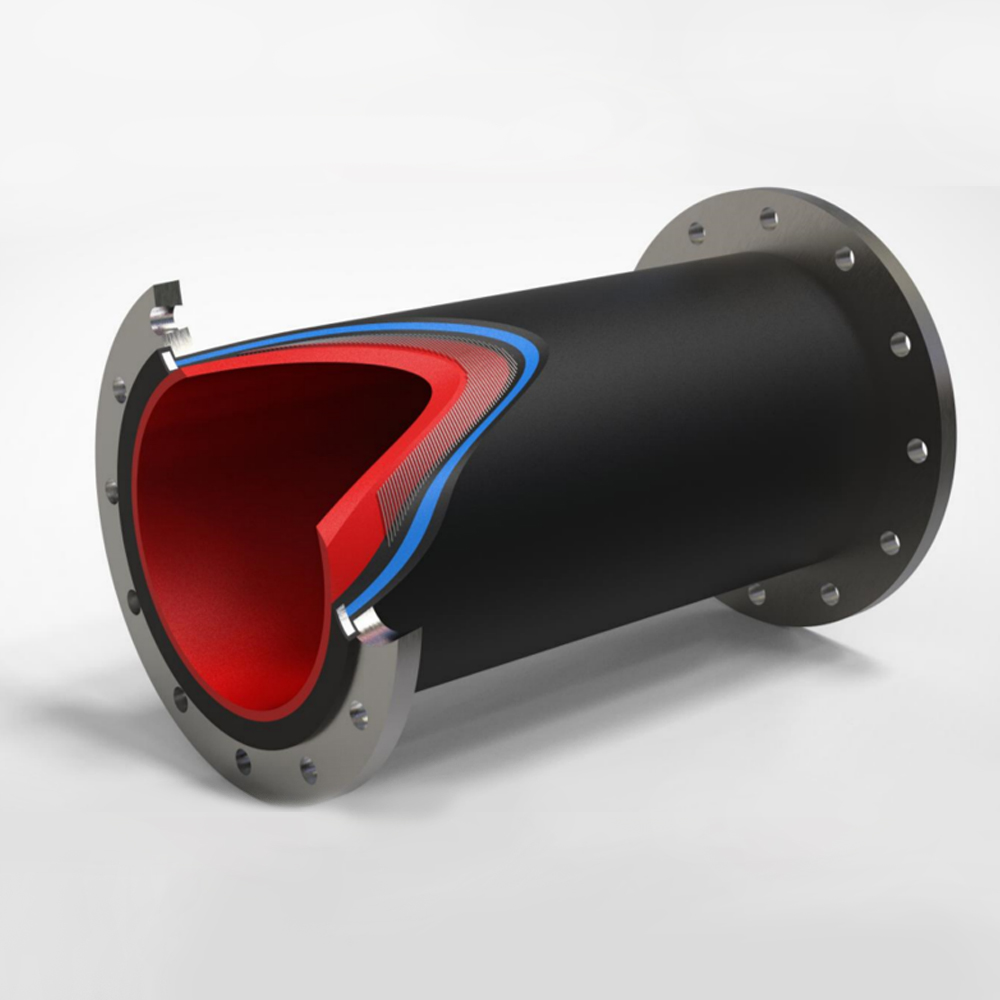

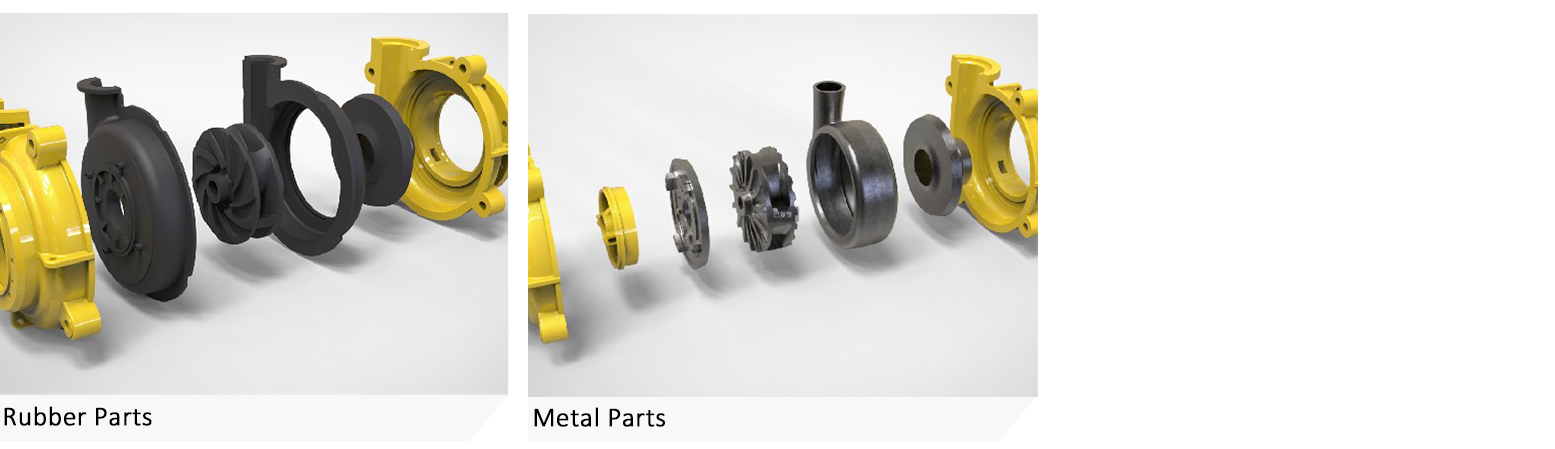

TIKTOP rubber and metal lined pumps feature casings which are radially split into two halves.Minimum casing bolts reduce maintenance and minimise downtime.Slurry pumps are heavy and robust centrifugal pumps capable of handling tough and abrasive duties.Moulded impellers and loose liners are available in various elastomers.Additionally,sintered silicon carbide ceramics are also an option.Loose metal liners and impellers are available in abrasive resistant alloys and various corrosion resistant metals.With the addition of sintered silicon carbide ceramics,there are more choices to meet different application requirements.

Versatility: mill discharge pump, general slurry pump, horizontal centrifugal slurry pump, horizontal heavy-duty mill recirculation slurry pump, centrifugal froth pump, horizontal ceramic slurry pump.

Maintenance and optimization:Easily interchangeable parts. Quick service and maintenance with local inventory and deployment.

Experience of numerous applications:Mining and mineral processing, sand and gravel, dredging, copper, iron ore, diamond, alumina, coal, gold, kaolin, pulp and paper, steel, sugar, chemical, FGD, sand blending, power, construction, tunneling.

Global expertise, local support:Pumping professionals in over 60 countries in the world.

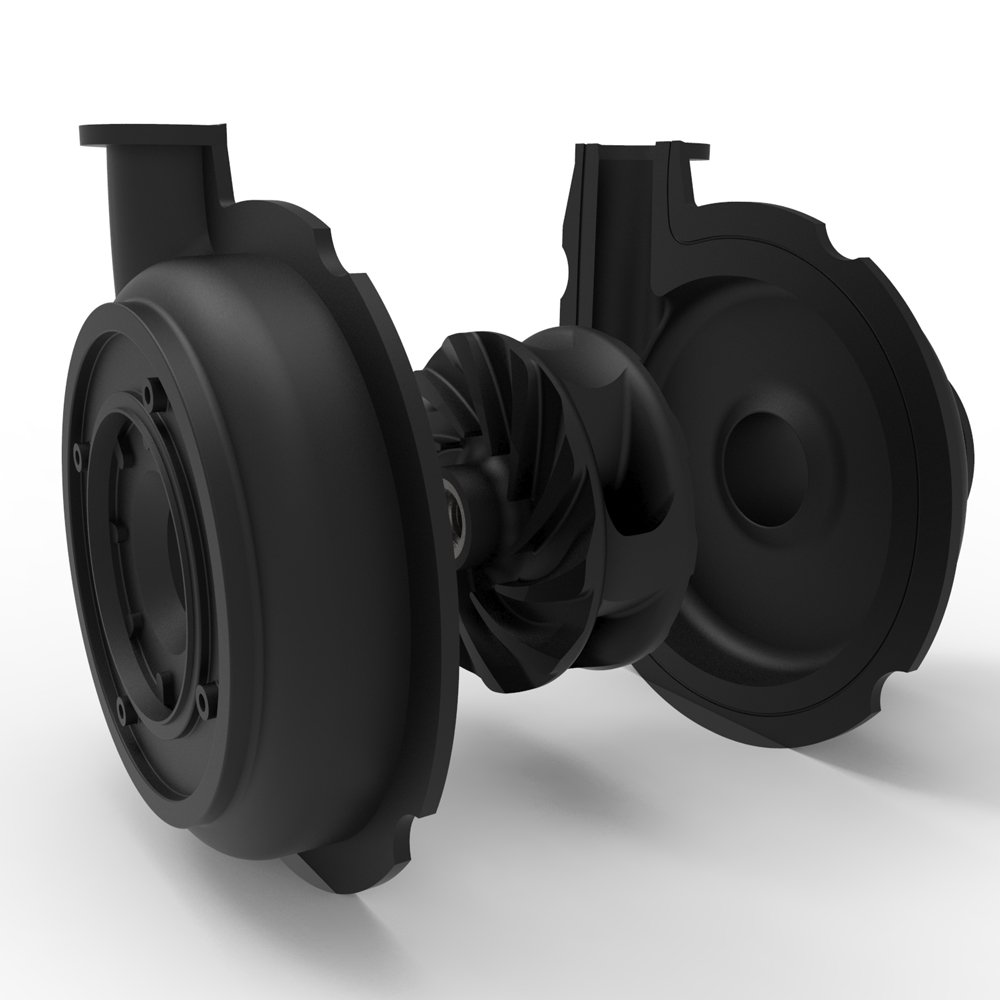

In traditional pumps, the outward helical flow of pulp can cause severe circulation when the impeller clearance is small and subsequently lead to wear.

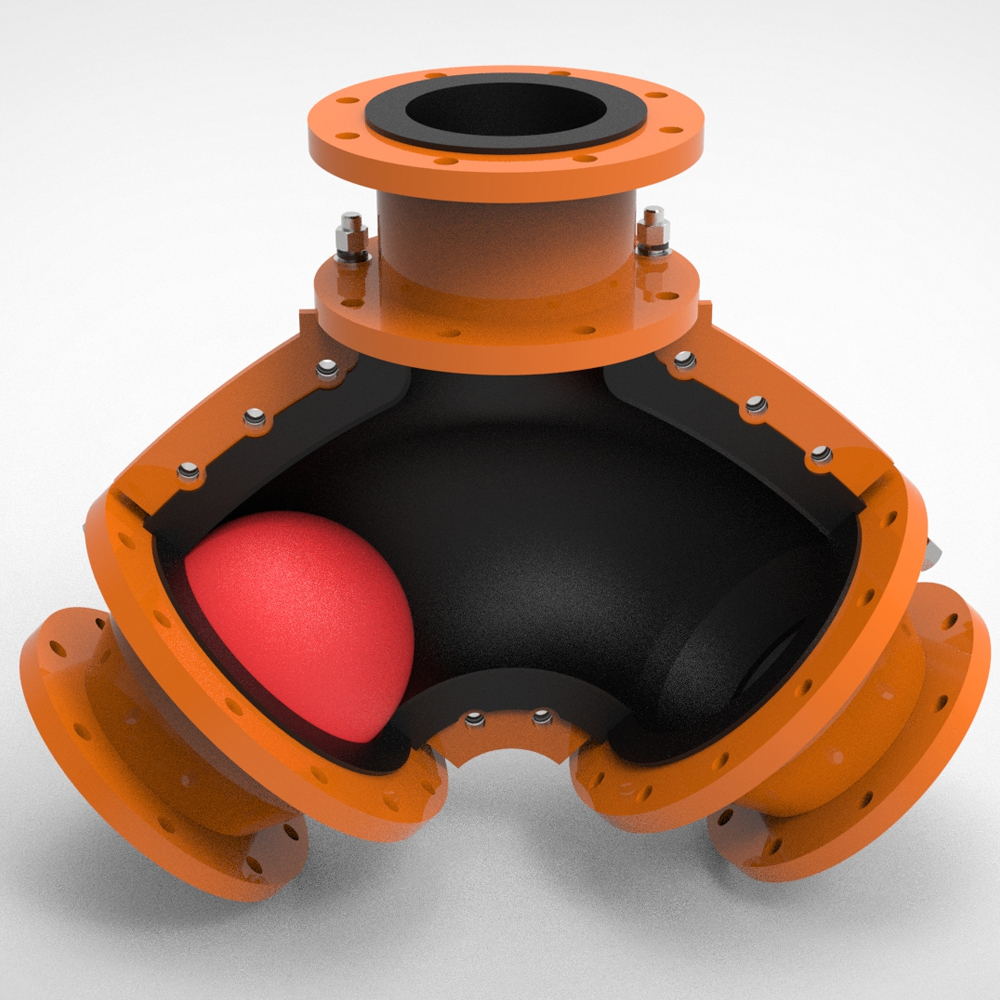

The rear guard plate pump outlet blades and the concave impeller blades of the ZB series pumps force the pulp to form a double inward spiral. This leads to uniform wear, enhances the utilization rate of vulnerable parts, prolongs the service life of the shaft seal, and maintains high efficiency throughout the entire service life of the component. For traditional pumps, the outward spiral flow mode of pulp has obvious drawbacks. Due to the generation of circulation, the slurry constantly impacts and rubs at the gap between the impeller and other components, resulting in severe wear. In contrast, the unique design of the ZB series pumps effectively resolves these issues. Due to more uniform wear, the pump can maintain a high efficiency throughout its entire service life, ensuring the stable operation of production. This innovative design of the ZB series pumps provides more reliable and efficient solutions for fields such as pulp treatment.

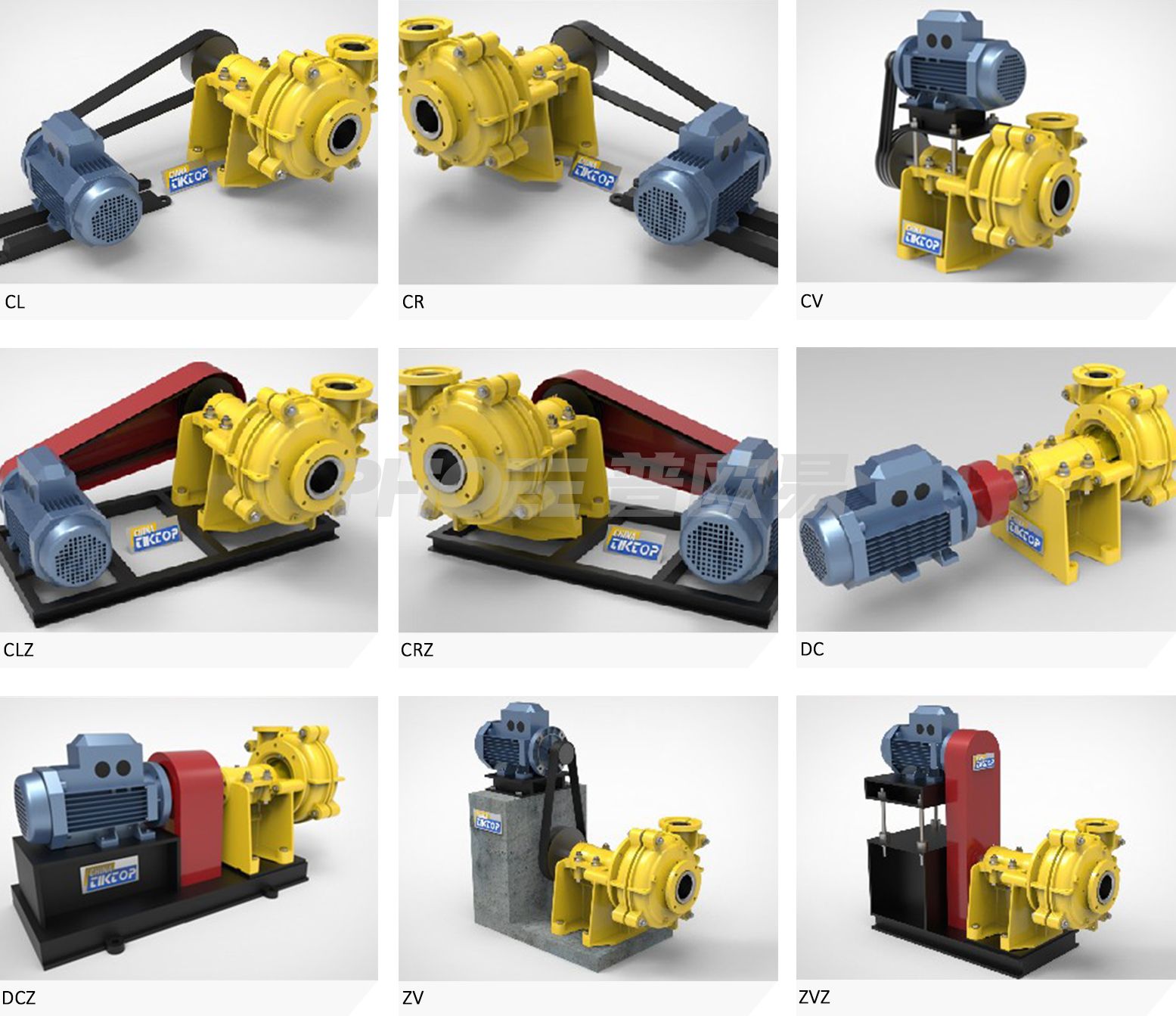

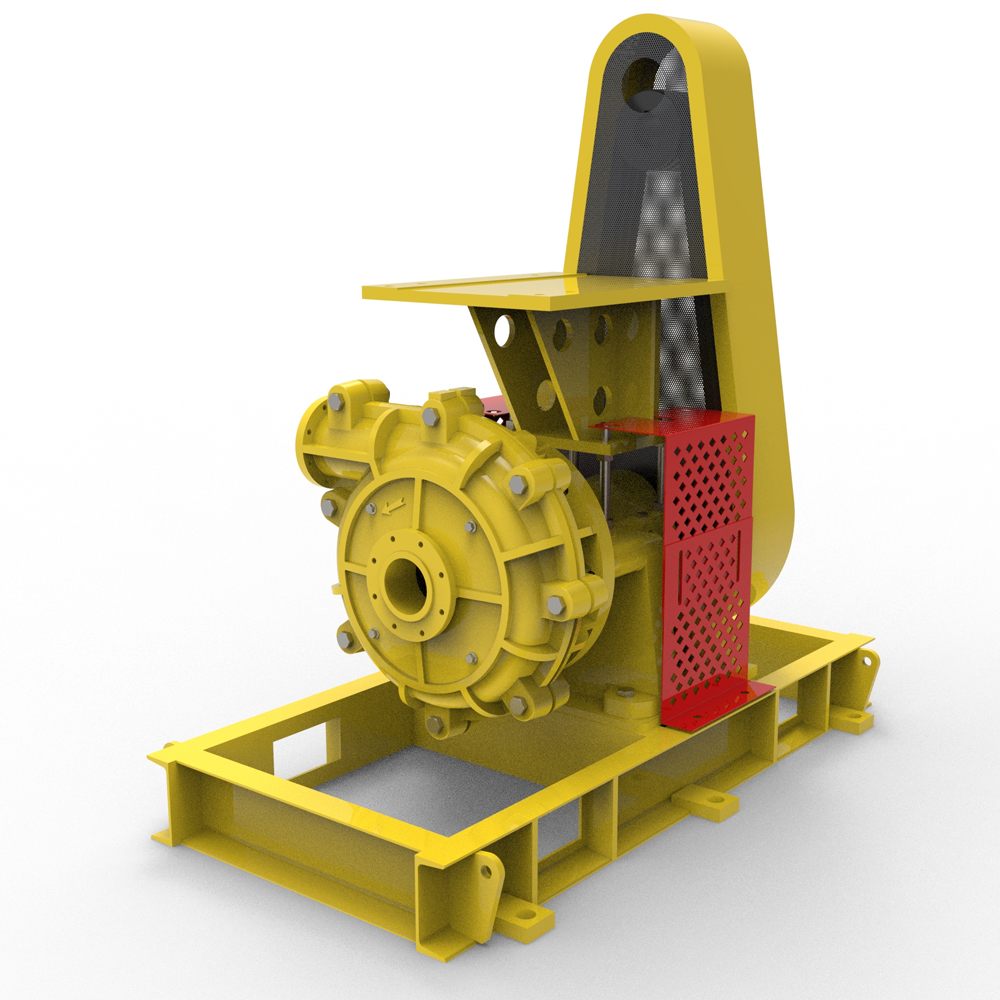

We are proud to offer a rich variety of installation methods for slurry pumps. Our team of experienced engineers has carefully designed and developed multiple installation options to ensure that our customers can find the perfect solution for their specific applications.

For some places with limited space, we can offer compact installation solutions to save space to the greatest extent. For applications that require high stability, we would recommend a more secure installation method to ensure that the pump does not shake or shift during operation.