Horizontal Froth Pump

ZPM Series Heavy Duty Froth Pump

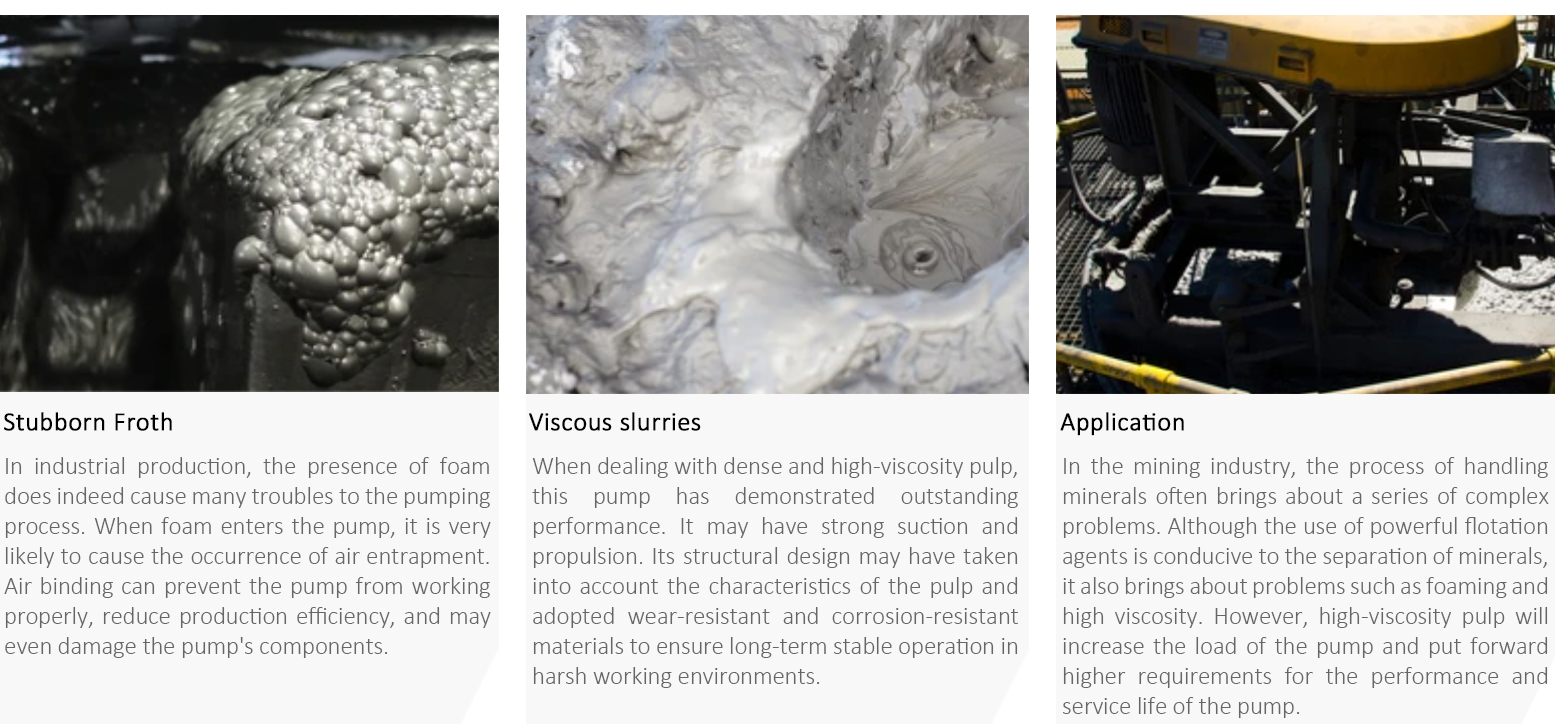

The mining industry is a primary example where pumping operations can be plagued by froth and high viscosity problems.

In the liberation of minerals from ore, the minerals are often floated through the use of strong flotation agents.Tough bubbles carry the copper, molybdenum or iron tails to be recovered and furtherprocessed.These tough bubbles create havoc with many slurry pumps, often leading to the selection of overly large and inefficient pumps.

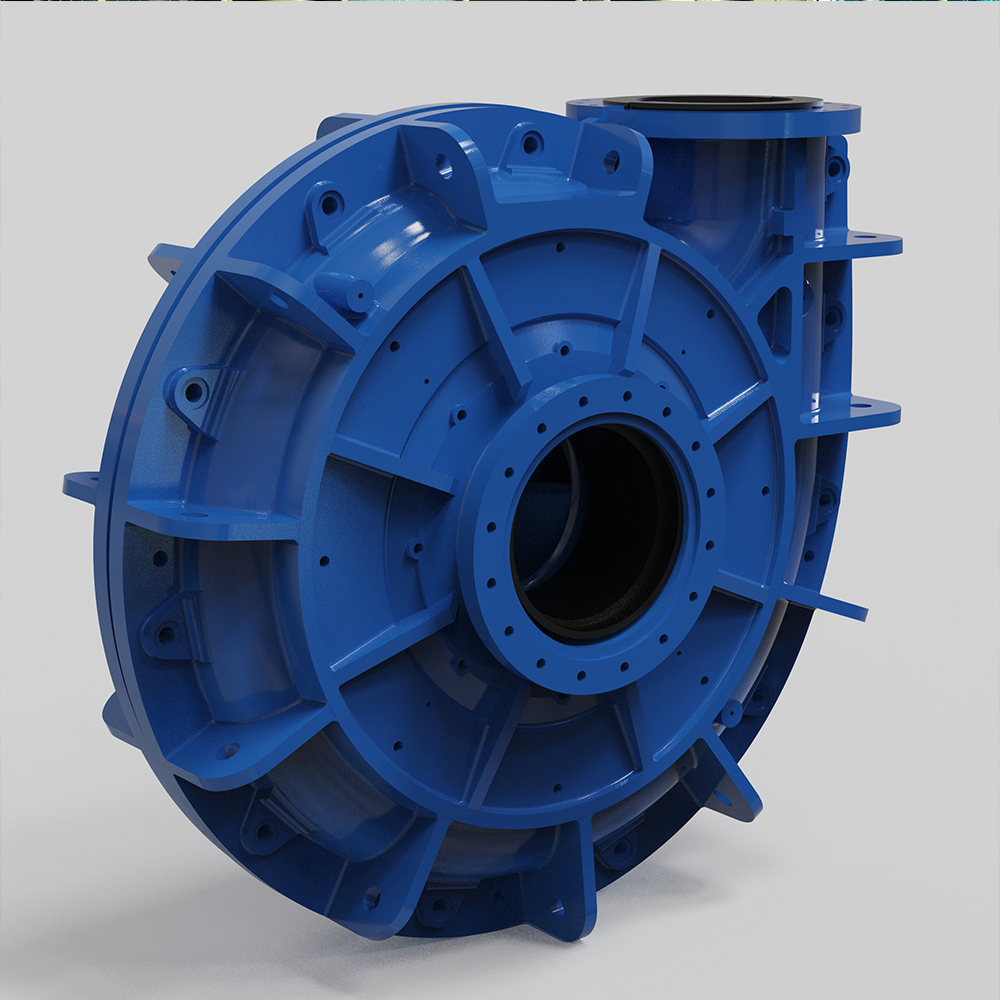

ZPM heavy duty horizontal pumps designed to handle difficult tenacious froth.

In the mining industry, the ZPM heavy-duty horizontal pump stands out for its excellent performance and reliable design. For industries that frequently face issues with viscous foam, such as mining and chemical processing, this pump has brought significant convenience to production processes. It effectively breaks down foam, ensuring smooth fluid transfer and improving production efficiency. When it comes to handling high-viscosity slurries, the ZPM heavy-duty horizontal pump demonstrates powerful capabilities and an optimized structural design, enabling it to easily handle high-viscosity media while reducing the risks of blockages and wear.

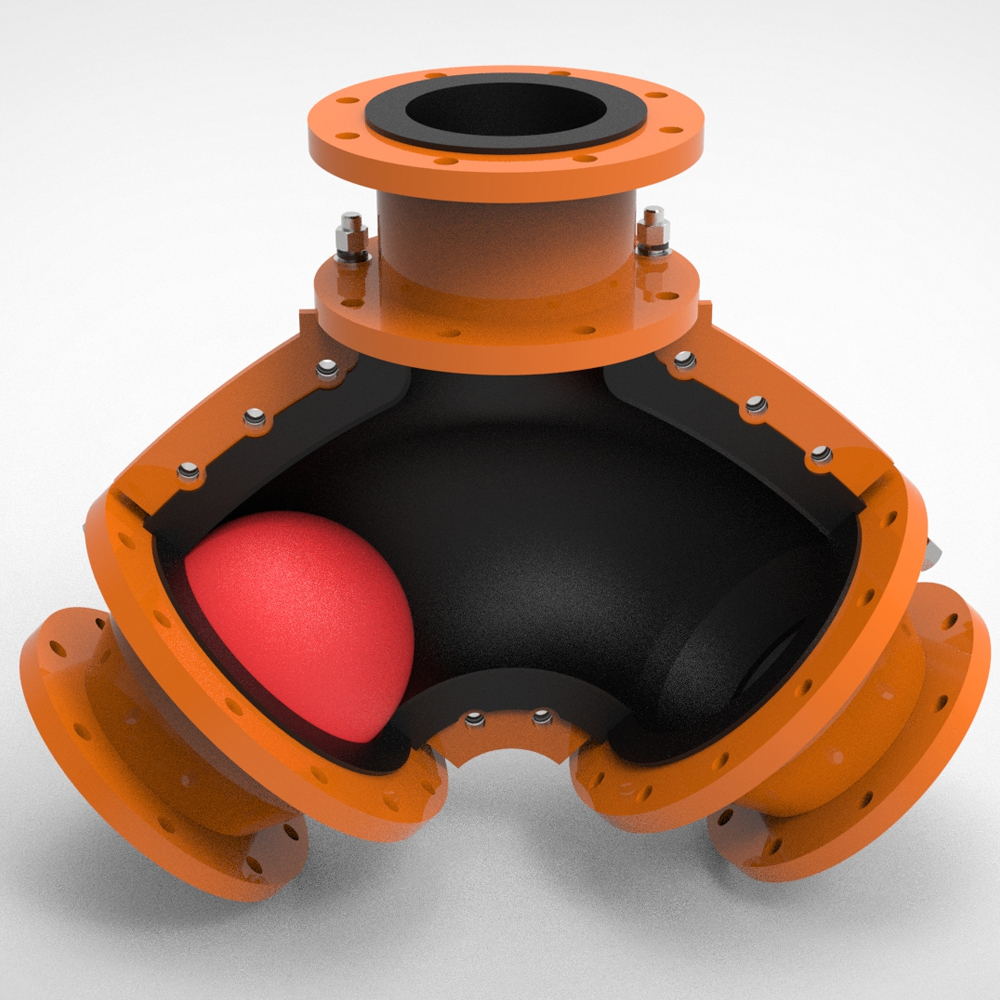

During the pumping process of froth or viscous slurries, the design of the inducer impeller and oversized inlet plays a critical role. The inducer impeller can generate strong suction, smoothly introducing the froth or viscous slurry into the pump. Its special shape and structure can effectively reduce the occurrence of air binding, enhancing the pump's suction performance.

During the pumping process of froth or viscous slurries, the design of the inducer impeller and oversized inlet plays a critical role. The inducer impeller can generate strong suction, smoothly introducing the froth or viscous slurry into the pump. Its special shape and structure can effectively reduce the occurrence of air binding, enhancing the pump's suction performance.

Unique inducer-type suction impeller

Modified with a new inducer blade based on the classic TIKTOP ZB series horizontal slurry pump to handle a large amount of unbreakable froth in some process flows in industries such as mineral processing and chemical engineering.

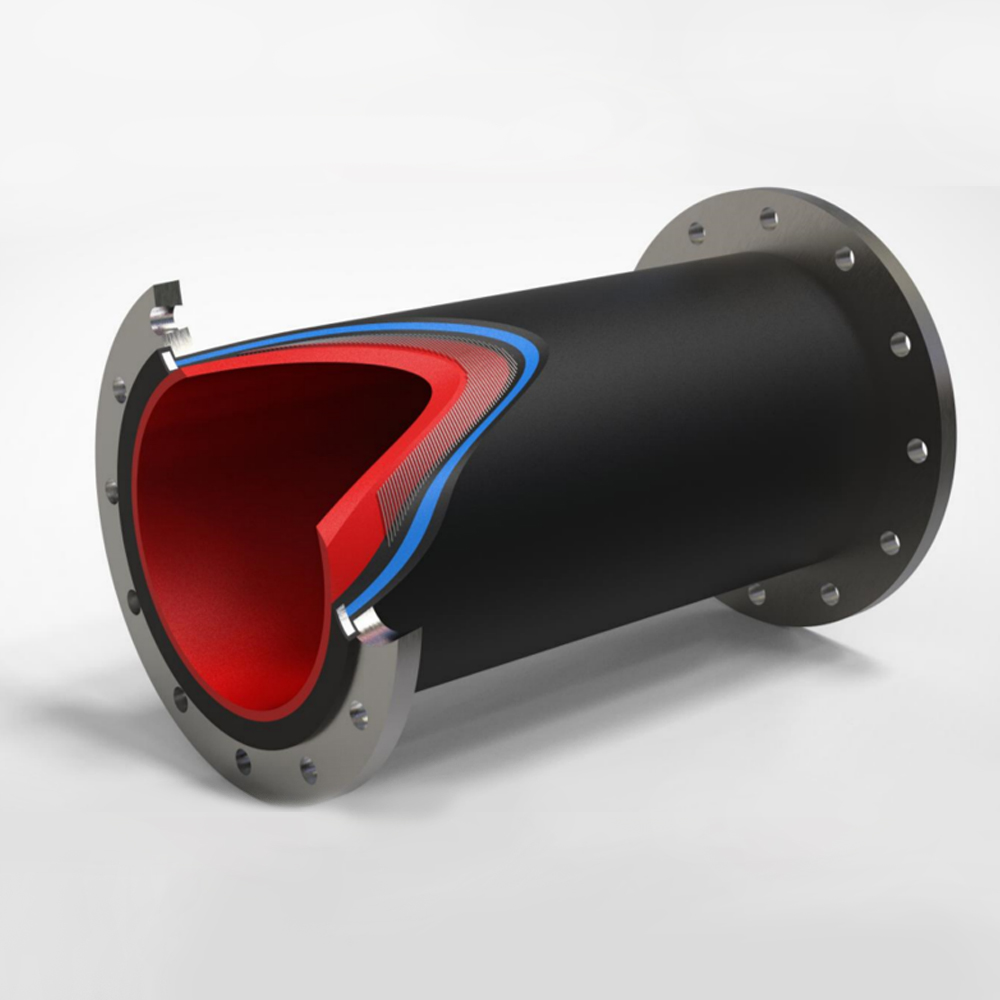

Through simple impeller modification, the following advantages can be achieved:

1、No air-binding at the impeller center.

2、Excellent performance for abrasive mineral froth slurry with a froth volume factor up to 4.0.

3、Stable performance in extreme froth conditions tested on site, without the need for additional reduction of the foam volume factor.

4、Impeller options include wear-resistant high-chromium alloy or silicon carbide ceramic.

5、The impeller design does not require tight running clearances, providing flexibility in selection.

6、Superior pump efficiency allows for a smaller motor size.

7、Good universality and modularity, and existing ZB series slurry pumps can be upgraded.

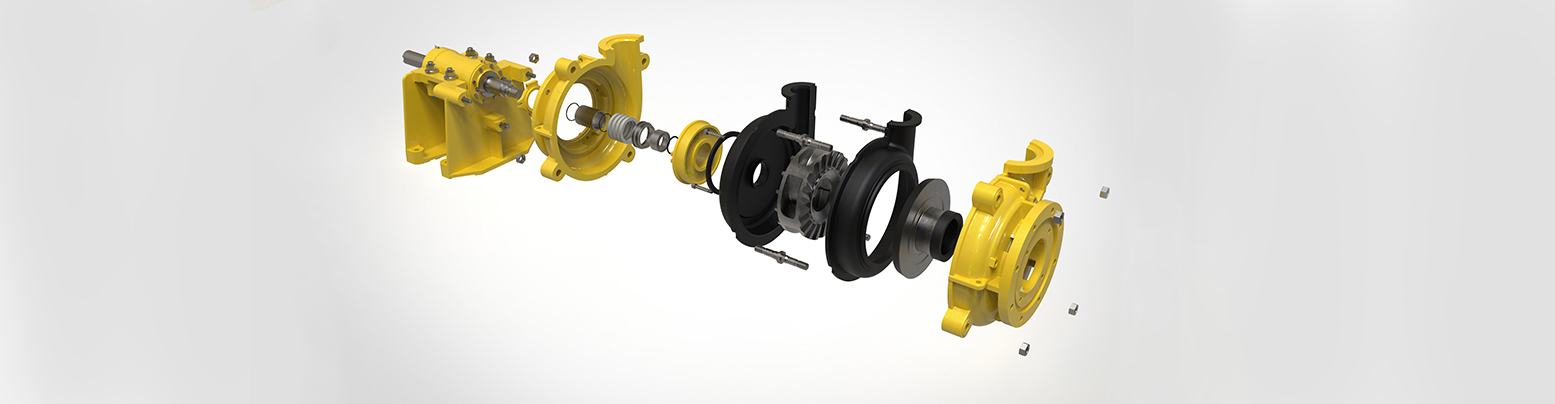

Easy Interchange

By simply replacing the impeller, throatbush, and cover plate, the ZB series slurry pump can be converted into the ZPM series. This convenient upgrade method brings many benefits to users, providing an economical and efficient solution. There is no need to purchase a brand new pump; performance improvement and functional expansion can be achieved by just replacing a few key components.