Pinch Valves

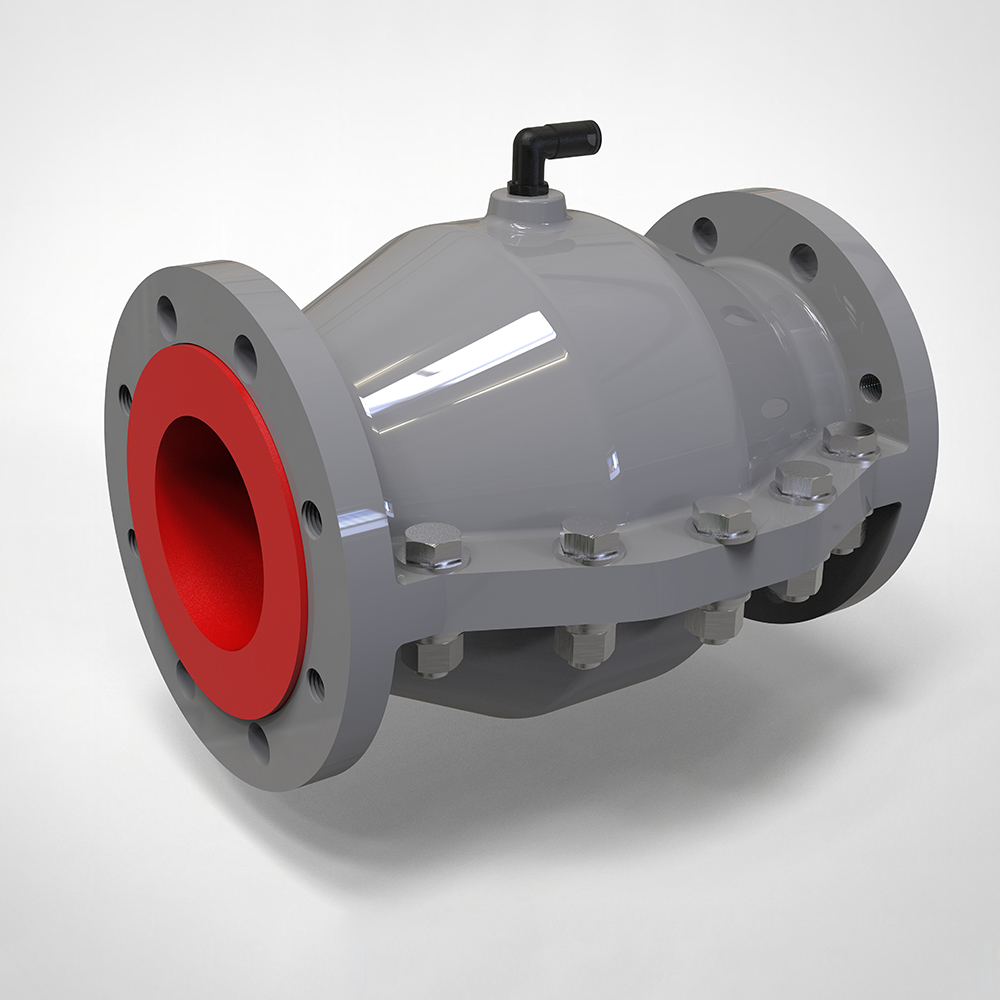

TIKTOP Pinch Valves are driven by electric and pneumatic control systems.

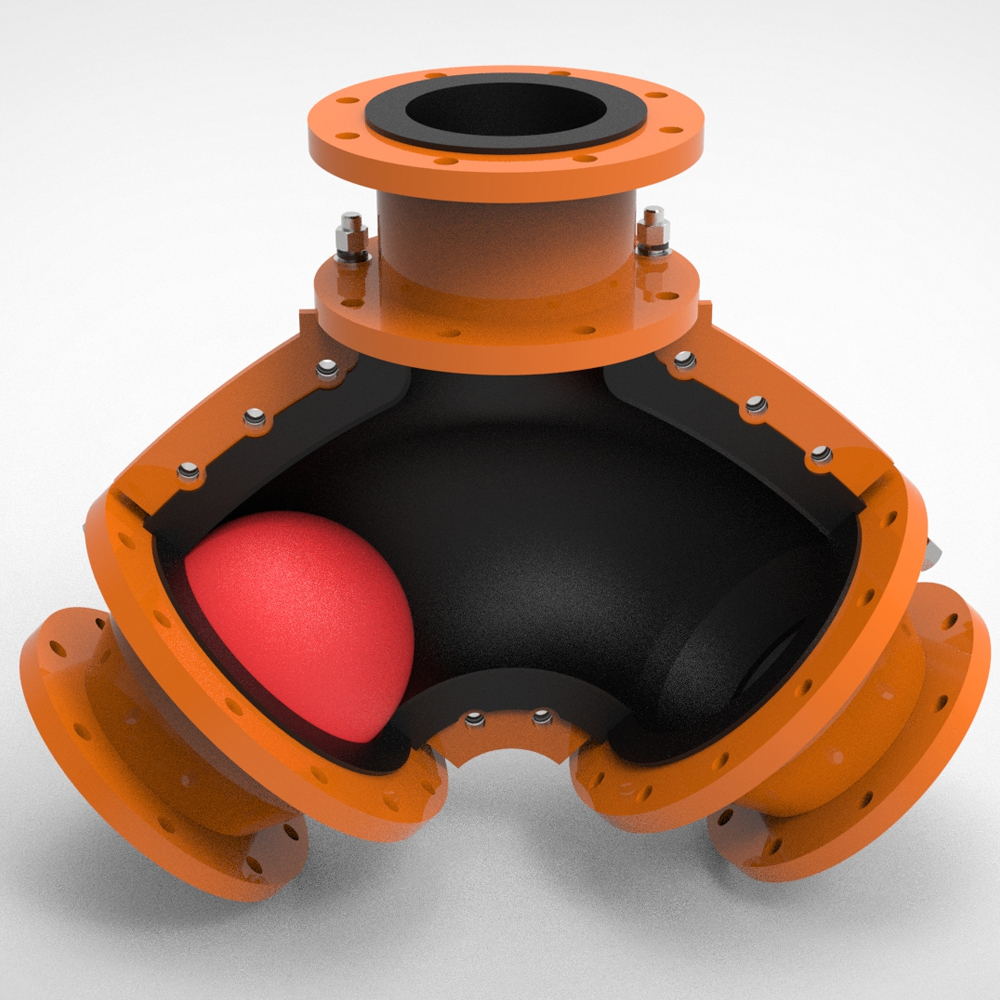

They control on/off by squeezing or loosening rubber hoses. The medium only passes through the hose. Other parts of the valve body do not come into contact with the medium.

This means that compared with other types of solenoid valves, pinch valves can handle media with particles without clogging.

What is pinch valves?

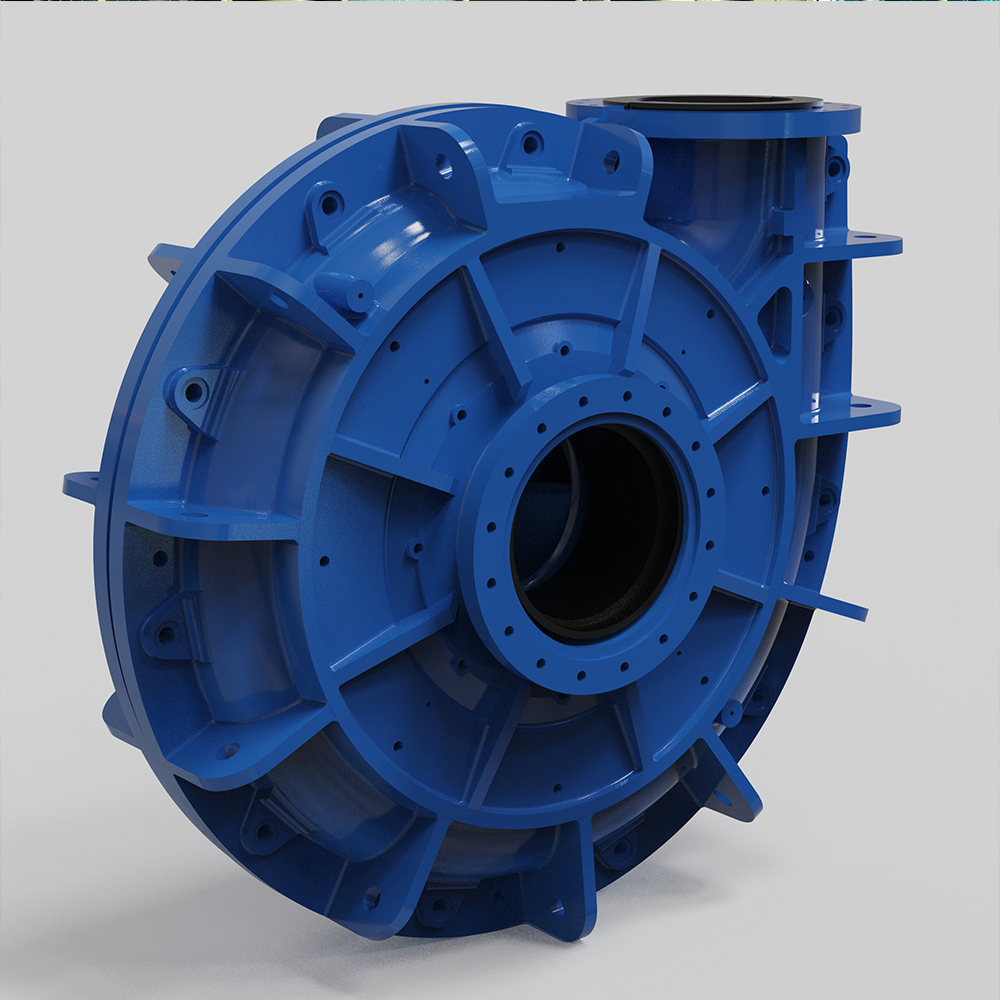

The TIKTOP pinch valve series is designed to address process challenges associated with controlling the flow of abrasive or corrosive fluids.

Numerous industries, such as mineral processing, pulp and paper, power generation, chemical processing, wastewater treatment, water supply, and sewage treatment, utilize TIKTOP pinch valves.

In the mineral processing industry, where it is often necessary to handle highly abrasive fluids containing large amounts of solid particles, TIKTOP pinch valves can effectively control fluid flow while reducing wear on the valve.

Electric Valve

Electric pinch valves are designed to control the flow of fluids by squeezing or releasing a flexible hose.

They are driven by an electric motor, providing precise control and reliable operation.

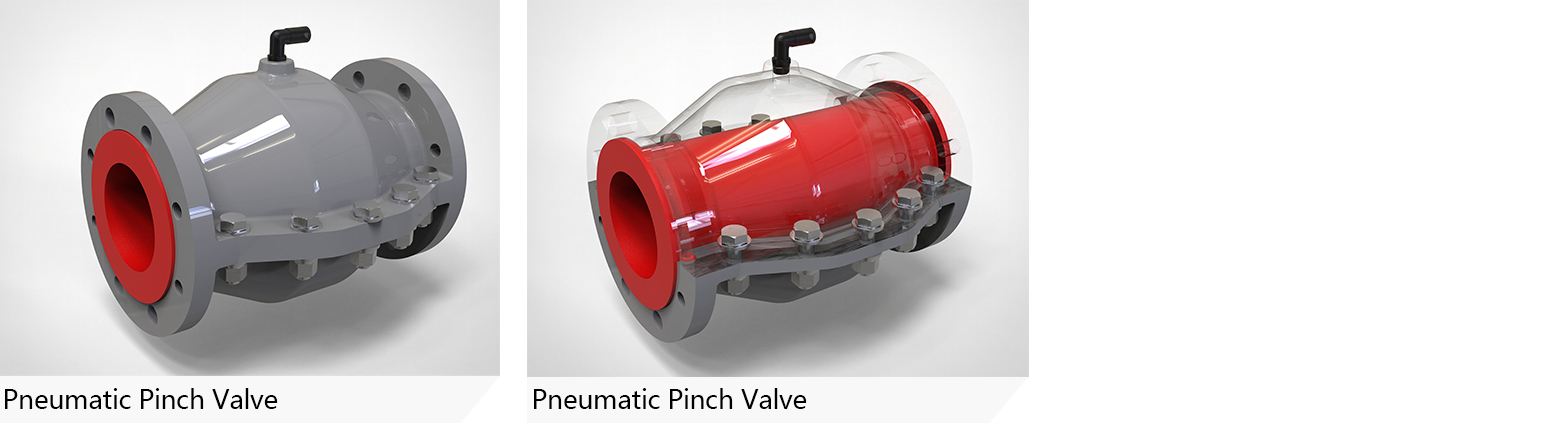

Pneumatic valve

A pneumatic pinch valve is a type of valve that uses pneumatic power to control the flow of a fluid.

It works by squeezing a flexible hose or tube to close off the flow or releasing the squeeze to allow the flow.

Product features

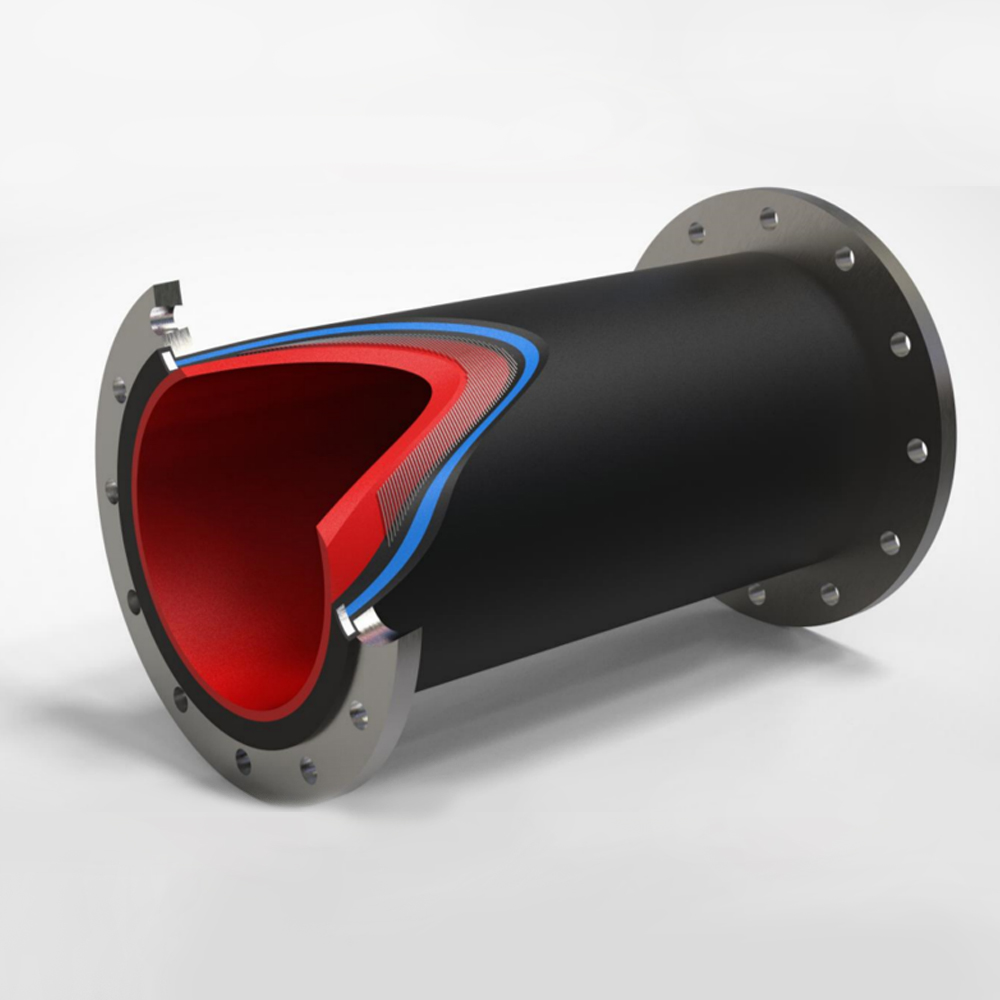

Pinch valves of other brands are called "weekend valves", while TIKTOP's valves can have a lifespan 10 to 15 times that of theirs.

Robust design:Manufactured with quality, heavy-duty materials.

Ease of maintenance:The new design facilitates easier adjustments for faster sleeve change outs.

Improved safety:No exposed moving parts on the valve.

Various materials available:Available in various materials to suite your application.

Low operation & maintenance costs

Sleeves are easily and quickly changed without the need to remove the valve from the pipeline or disconnect hoses or cabling.

Flow is improved due to the exceptionally low pressure drop.

Maintenance downtime is minimized thanks to the long-lasting abrasion resistant sleeve material which increases the lifetime of the valve.

Wear is minimized due to the smooth full-bore.

Pumping costs are reduced due to the unobstructed flow.

Plant availability is increased as there are no glands or seats which require regular adjustment or replacement.

Spare part inventory is reduced thanks to only needing one single wear part.

Fewer operators and lifting equipment is required to change the sleeve due to the fast change system which can be done in a matter of minutes.