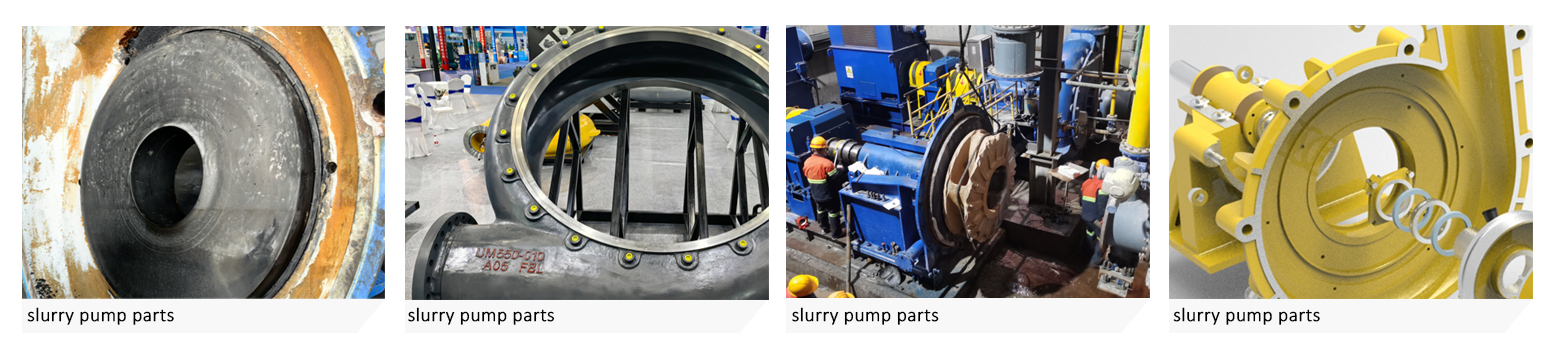

Horizontal Slurry Pump Parts

General and wear-resistant parts for horizontal slurry pumps.

In industrial scenarios involving the handling of erosive mineral pulps, slurry pumps inevitably experience wear. Over time, the replacement of spare parts and consumable components becomes necessary. A fully integrated system and a single-source supply solution offer numerous conveniences to customers.Customers do not need to deal with multiple suppliers to find various spare parts. Single-source supply ensures that the specifications of spare parts are unified and the quality is reliable, reducing the complexity and cost of inventory.Optimized delivery processes. An integrated system can more efficiently organize the delivery of spare parts, ensuring timely delivery when customers need them, reducing downtime caused by waiting for spare parts.

Although wear and spare parts may appear identical on the outside, in reality, they can be vastly different in terms of quality and materials.

You Faced Questions

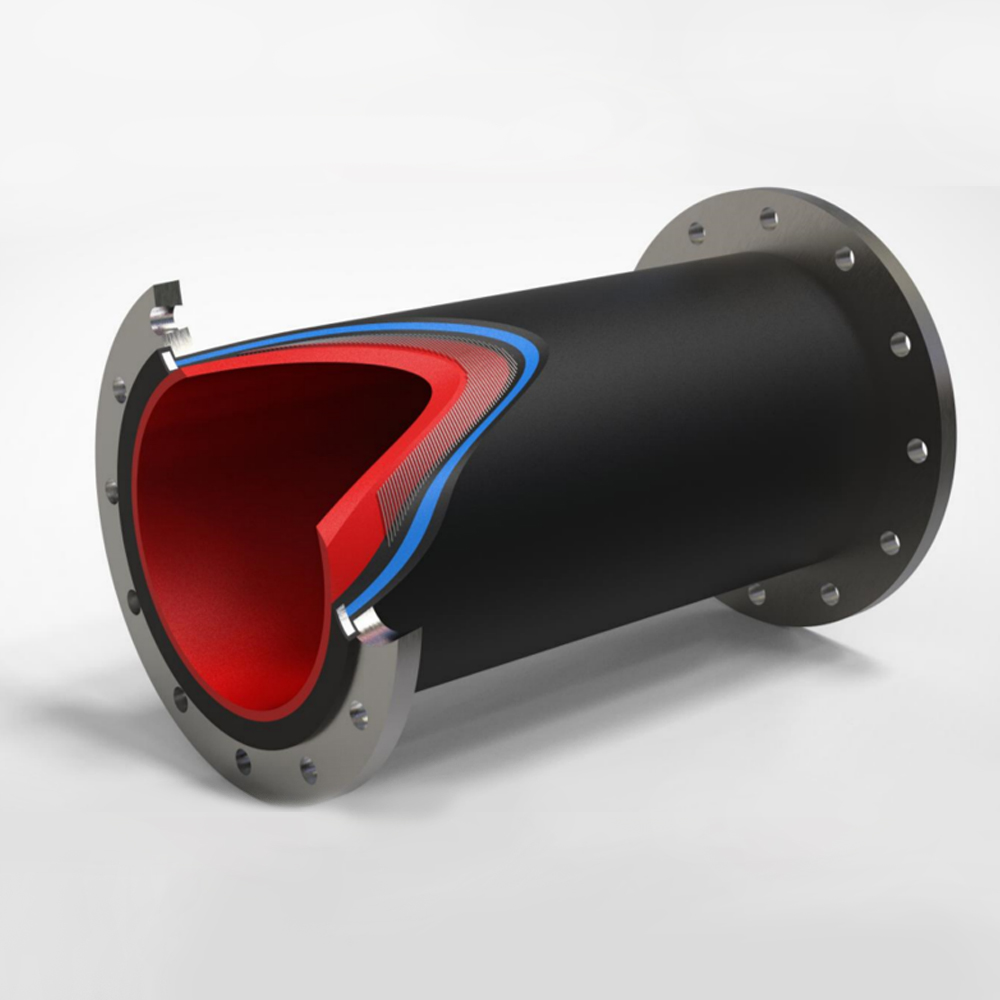

Does parts fit?

When the performance of consumable components is improved, the overall operating efficiency of the pump will also increase. This means that energy consumption can be reduced, maintenance frequency and downtime can be decreased, thereby improving production efficiency and reducing costs. Human judgment is often not accurate enough; it requires reliance on precision measuring tools and strict manufacturing tolerances to ensure the correct fit of components. If a component's dimensions exceed the tolerance range, it may lead to loose installation, leakage, increased friction, and other issues, thus affecting the equipment's performance and lifespan. When selecting and installing components, it is essential to strictly adhere to specification requirements, ensuring each component meets the correct size and tolerance standards.

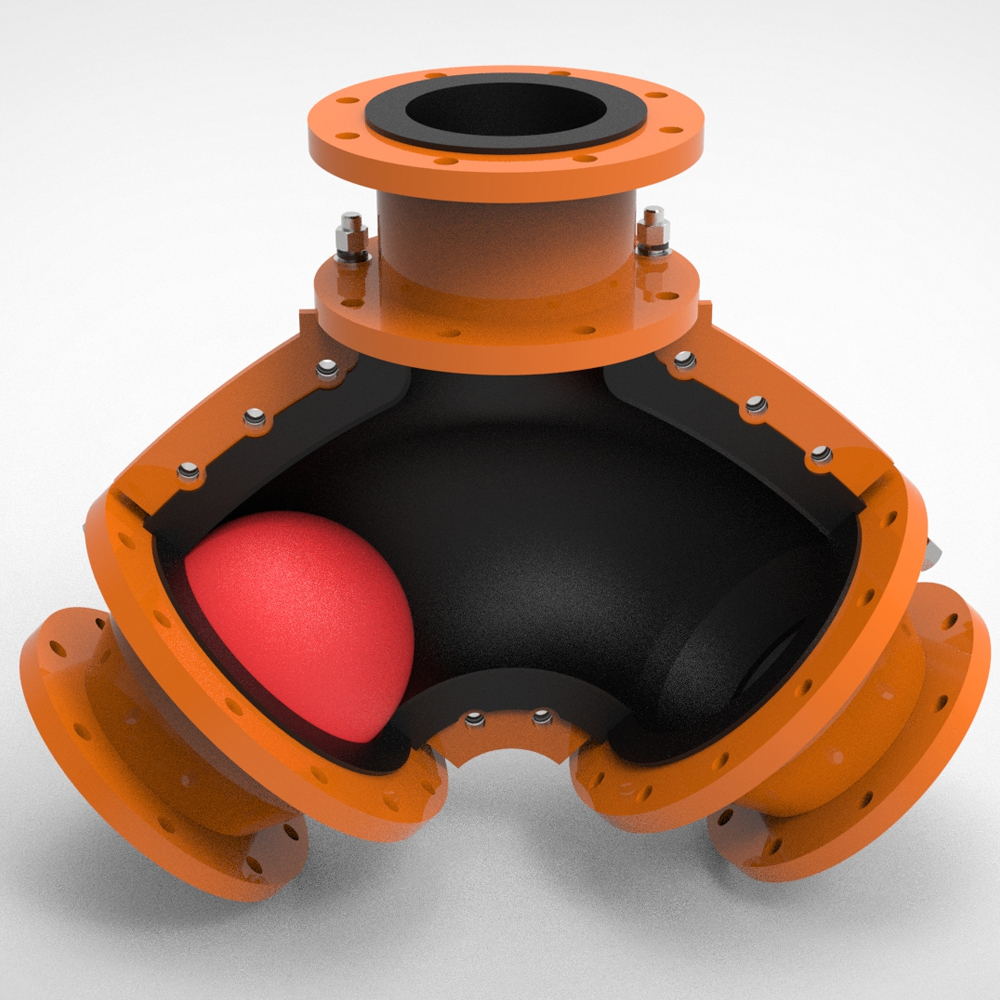

Is the parts material correct?

In order to ensure the quality and performance of replacement parts, components with similar metallurgical characteristics or proven performance to the original parts should be selected.For applications that require good wear protection, such as slurry pump parts, the composition of the alloy plays a key role. Alloys containing appropriate amounts of chromium and other specific elements can provide excellent wear and corrosion resistance. It is difficult to judge the performance differences of different alloys by appearance alone; seemingly identical alloys may exhibit completely different effects in terms of wear protection. In actual applications, incorrectly choosing an alloy can lead to premature part failure, increasing maintenance costs and downtime.

How about support services?

Always consider whether a company has the resources and competen to support you. When a critical component fails, it is very important to know that the supplier has readily available inventory. Because if there is an issue with a critical component, it could cause the entire system or process to come to a halt. If the supplier can promptly provide the required components at this time, it can greatly reduce losses and delays. For components that do not fail frequently, suppliers should also have the ability to quickly obtain these components.

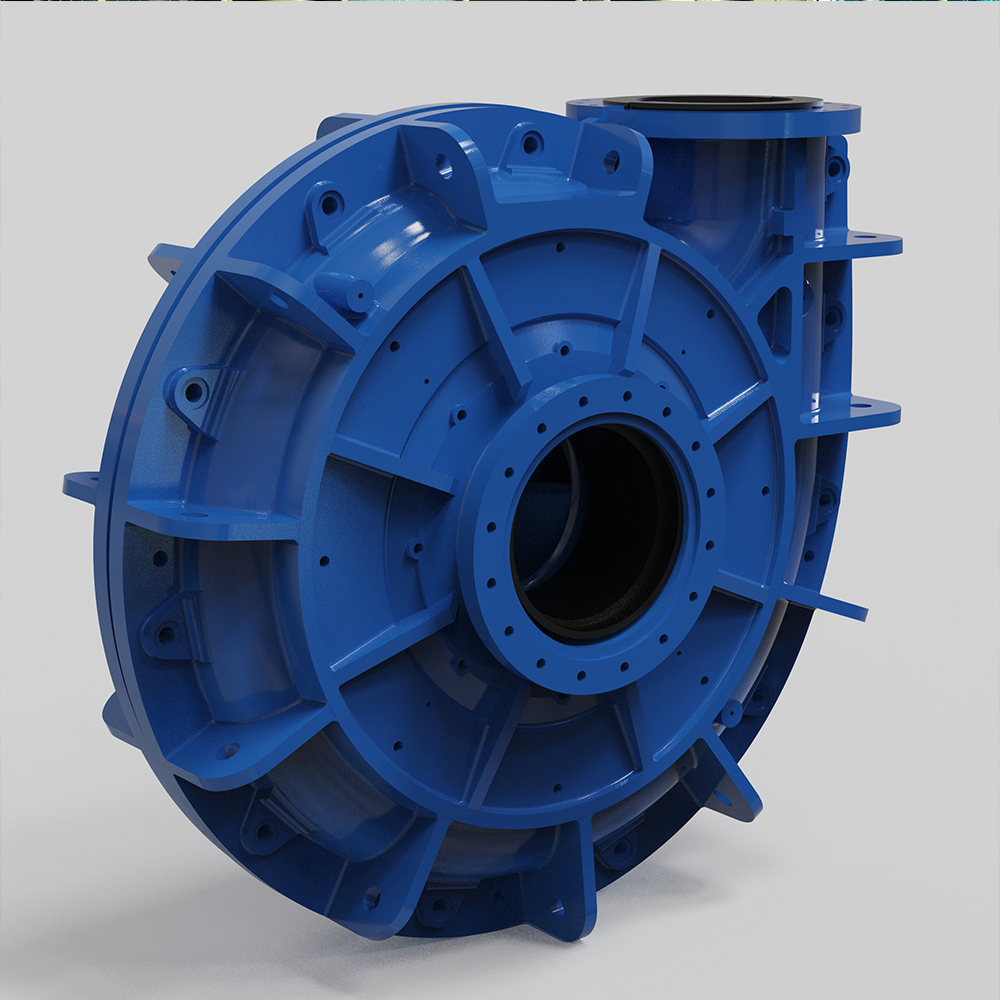

Is the part structure reasonable?

A seemingly insignificant small change can have a huge impact on the actual performance of a component.

For each specific wear-prone component or spare part, there are often some small features that ensure the part functions properly. If these features are arbitrarily removed, it is highly likely to cause the equipment where this part is located to fail to operate normally. In severe cases, it may even lead to equipment failure. In actual production and use, we cannot easily remove these features just because they seem insignificant or are considered troublesome.