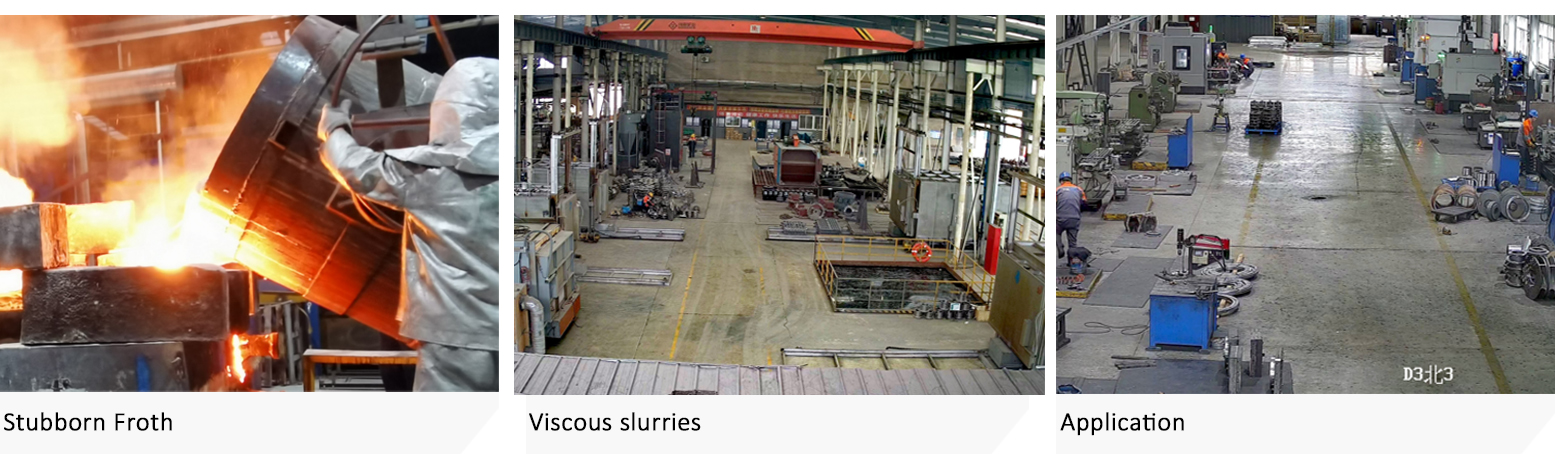

Own foundries ensure reliable parts

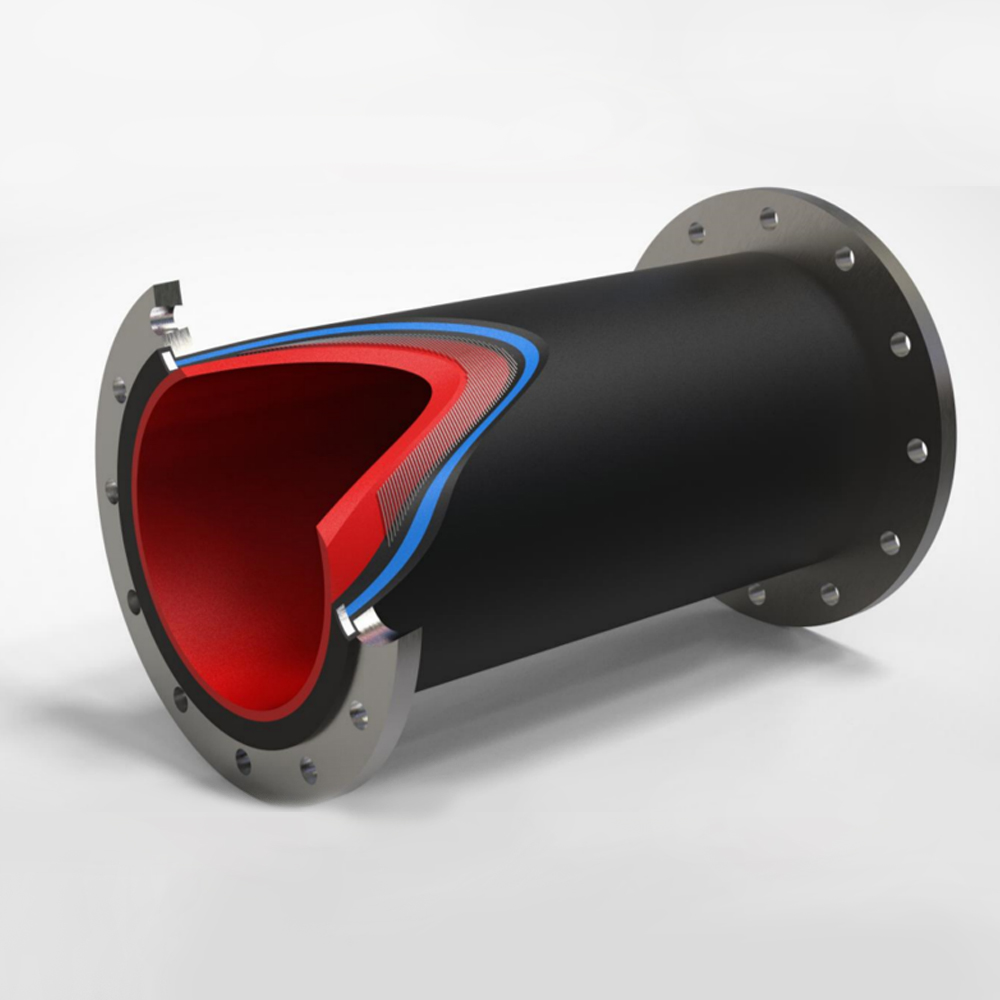

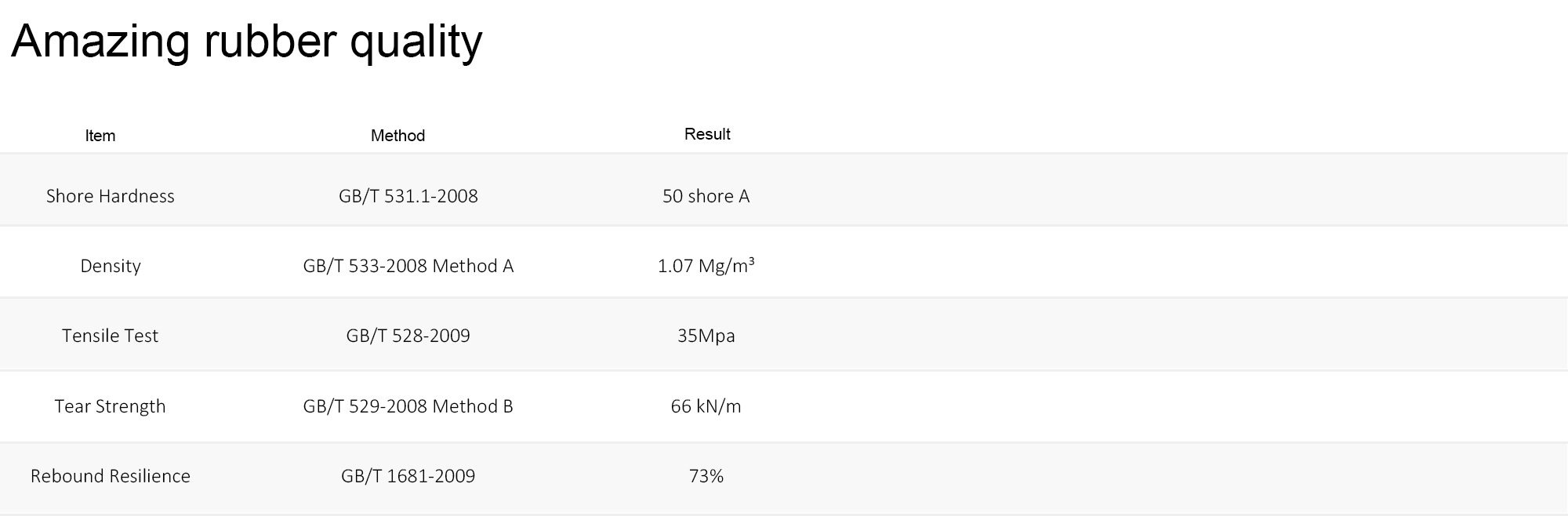

High-performance rubber materials are manufactured by using liquid-phase mixing

Liquid-phase mixing, as an advanced process, has many advantages. It allows for better control of parameters during processing. By precisely adjusting parameters such as temperature, pressure, and mixing time, the properties of rubber materials can be finely tuned. In this way, rubber materials with specific properties can be manufactured according to different application scenarios and specific requirements. In the production of liquid-phase latex, various additives and fillers can be more uniformly dispersed in the rubber matrix through specific technical means. This is crucial because uniformly dispersed additives and fillers can greatly improve the mechanical properties of rubber.

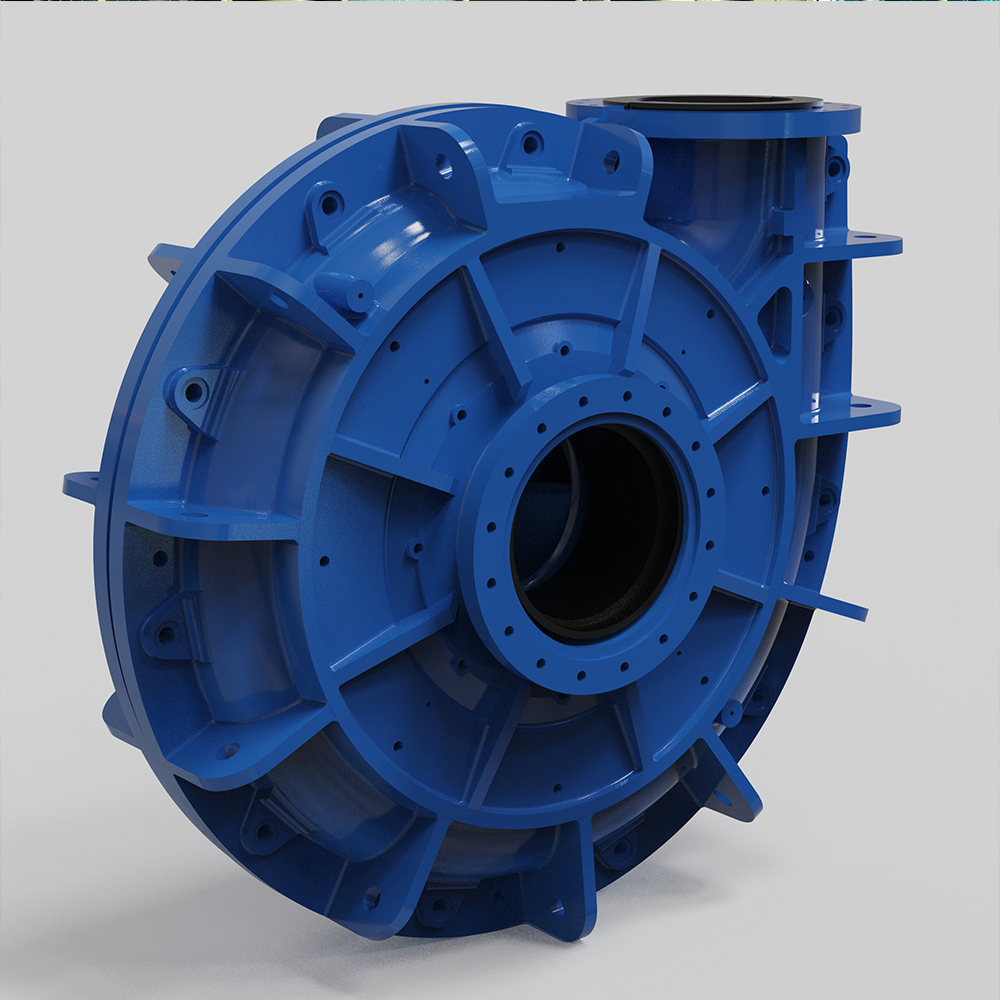

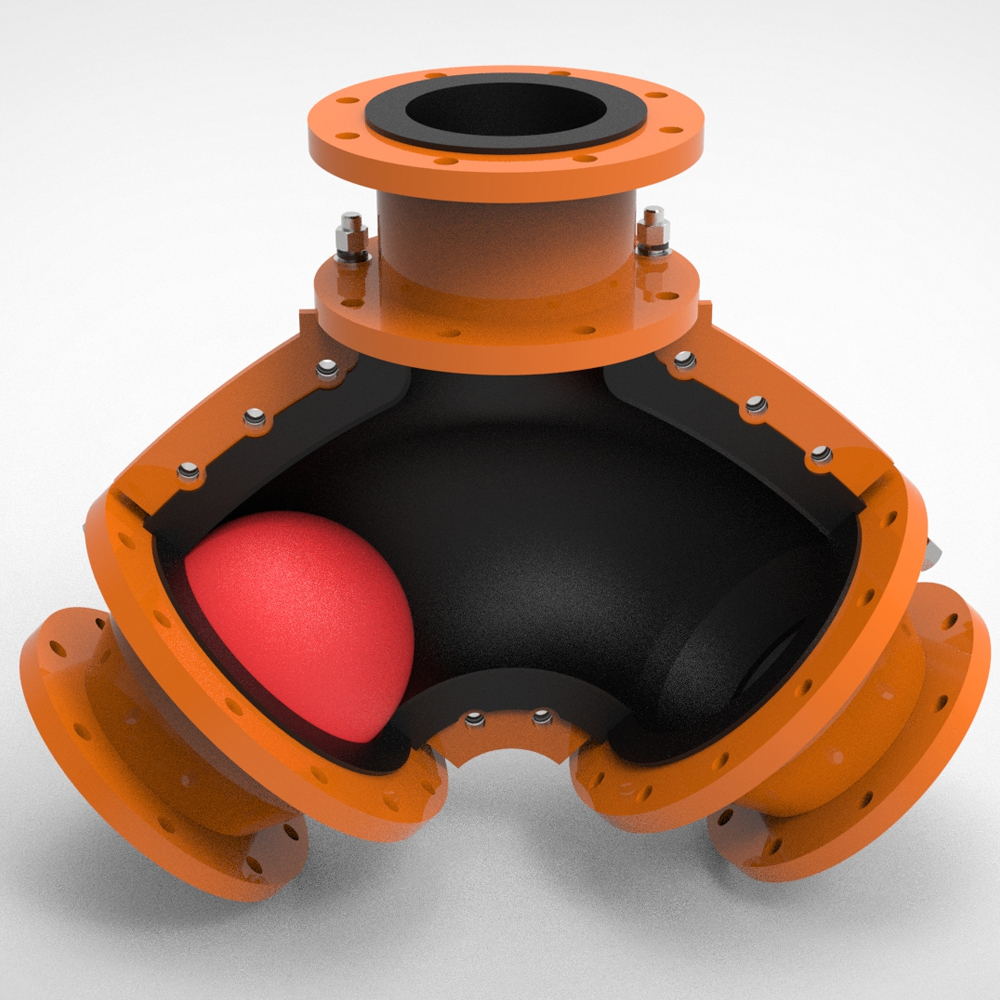

TIKTOP metal wear pump parts are produced at our own foundries. Our high- chromium white irons are specially developed for mill lining and slurry pump applications and are carefully selected based on the operating conditions of each pump.

Own Heat Treatment

In order to ensure the actual effect of heat treatment, TIKTOP adopt own heat treatment methods exceeding the standard.

Our own machining center

TIKTOP is equipped with extremely precise CNC equipment for processing pump components. In today's industrial manufacturing sector, accuracy and quality are crucial considerations.

Ceramic pump wear parts